- Carbon & Carbon Alloy Steel

- Stainless Steel

- Copper & Nickel Alloy

- Heat Efficiency Tubes

- Pipe Fittings

- Pipe Flanges

- Gasket, Stud Bolt &Nut

- Industrial Valves

01

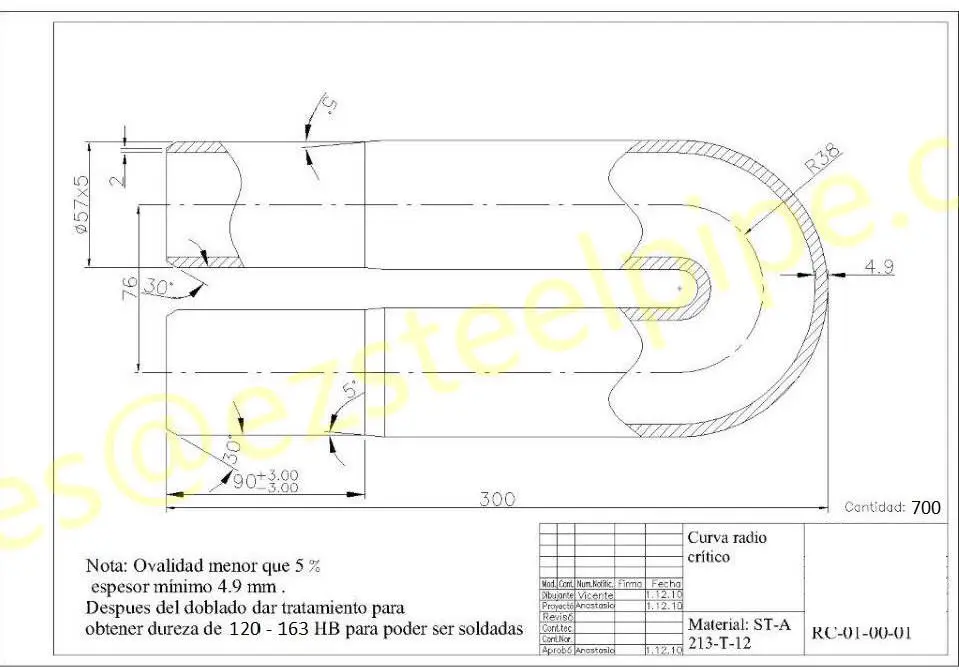

U-type J-type Bend Tubing

Materials Selection

- Common materials: Stainless steel (SS304, SS316), carbon steel, copper alloys, titanium, or nickel alloys (depending on fluid corrosiveness and temperature).

- Ensure material meets ASME/ANSI, ASTM, or other industry standards.

Tube Bending Process

For U-Tubes:

- Mandrel Bending: Ensures smooth bends without wrinkles.

- Cold Bending (for small diameters): Uses hydraulic or rotary draw benders.

- Hot Bending (for large diameters/thick walls): Heating before bending prevents cracking.

- Minimum Bend Radius: Typically 1.5 to 3 times the tube outer diameter (OD) to avoid deformation.

For J-Tubes (Single Bend, 180° Return):

- Similar to U-tubes but with one straight leg longer than the other.

- Used where space constraints exist.

Key Manufacturing Steps

1. Cutting the Tube

- Tubes are cut to required lengths (including bend allowance).

- Ends deburred for smooth welding.

2. Bending the Tube

- CNG or hydraulic tube benders ensure precision.

- Laser/optical measurement checks bend angles and radii.

3. Heat Treatment (if needed)

- Stress relieving (for high-pressure/temperature applications).

- Annealing (for work-hardened materials like stainless steel).

4. End Preparation

- Beveling for welding (if tubes are welded to tube sheets).

- Expanding/rolling into tube sheets for a tight fit.

5. Testing & Inspection

- Hydrostatic/Pneumatic Testing: Checks for leaks.

- Dimensional Checks: Ensures bend radius and straight lengths meet specs.

- NDT (Non-Destructive Testing):

- Dye penetrant (PT) or Radiography (RT) for weld integrity.

- Ultrasonic Testing (UT) for wall thickness uniformity.

Assembly in Heat Exchanger

- U-tubes are inserted into the tube sheet and expanded/welded.

- The J-tube (if used for cleaning/inspection) may be installed as a removable bundle.

- Tube supports/baffles are added to prevent vibration.

Alternative Methods

- Prefabricated U/J-tubes: Available from suppliers for standard sizes.

- Welded Return Bends: For large diameters where bending is difficult.

Key Considerations

- Thermal Expansion: U-tubes naturally accommodate expansion.

- Fluid Flow: Ensure smooth bends to avoid pressure drop.

- Cleanability: U-tube bundles allow for chemical/mechanical cleaning.

- Standards Compliance: ASME Sec VIII (Pressure Vessels), TEMA (Heat Exchanger Standards).

Want to order the same ? Contact us Now to send your request!