- Carbon & Carbon Alloy Steel

- Stainless Steel

- Copper & Nickel Alloy

- Heat Efficiency Tubes

- Pipe Fittings

- Pipe Flanges

- Gasket, Stud Bolt &Nut

- Industrial Valves

01

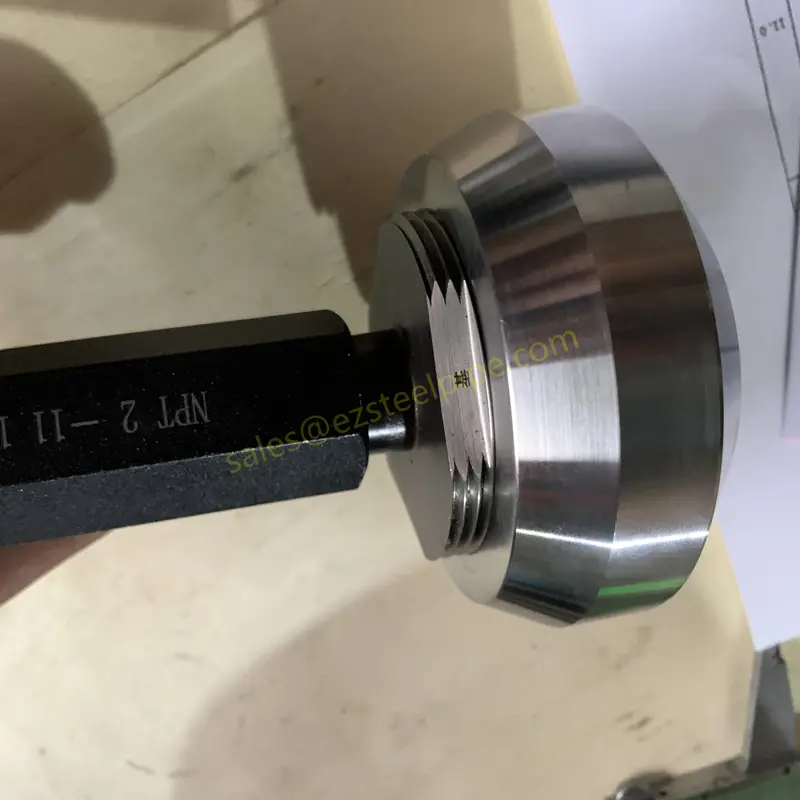

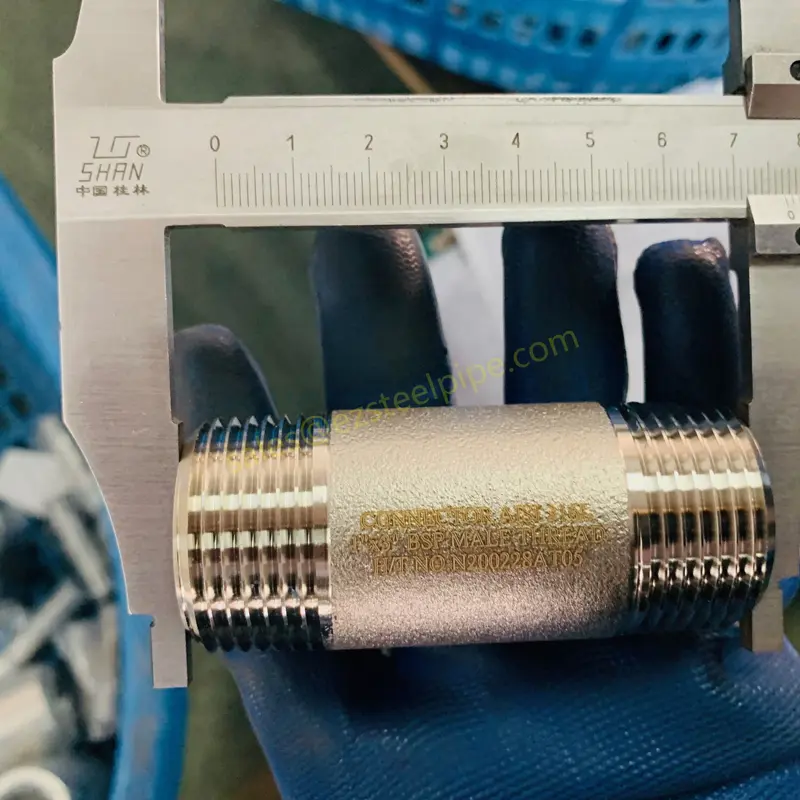

Threaded Pipe Fittings

Manufacturing Standards for Threaded Fittings

a) ASME/ANSI Standards (USA & International)

- ASME B1.20.1: Defines NPT (National Pipe Tapered Thread) dimensions.

- ASME B16.11: Covers forged threaded fittings (similar to socket-weld).

- MSS SP-42: Stainless steel threaded/bonded fittings.

- ASTM A105/A182: Material standards for carbon/stainless steel.

b) BSP Standards (Europe/Asia)

- ISO 7-1 (BSPT): British Standard Pipe Tapered Thread (similar to NPT but different angle).

- ISO 228-1 (BSPP): British Standard Pipe Parallel Thread (requires sealant/O-ring).

c) JIS (Japanese Standard)

- JIS B0203: Metric tapered threads (PT).

- JIS B2306: Threaded steel pipe fittings.

Size Range of Threaded Fittings

| Fitting Type | Common Size Range (NPS) | Max. Typical Size |

| Threaded Elbow | ⅛" to 12" | 12" (limited beyond) |

| Threaded Tee | ⅛" to 12" | 12" |

| Threaded Coupling | ⅛" to 12" | 12" |

| Threaded Reducer | ⅛" to 12" | 12" |

| Threaded Cap | ⅛" to 12" | 12" |

| Threaded Union | ⅛" to 4" | 4" (larger = impractical) |

Notes:

- Most common sizes: ½" to 4" (NPT/BSP).

- NPS > 4" is possible but rare due to sealing challenges.

- BSP fittings are common in Europe/Australia, while NPT dominates in the USA.

Thread Types & Sealing Methods

| Thread Type | Description | Sealing Method |

| NPT (Tapered) | Tapered thread (1.79° angle) | Thread sealant (Teflon tape, pipe dope) |

| BSPT (Tapered) | British Standard (1.47° angle) | Thread sealant |

| BSPP (Parallel) | Straight thread (G-series) | O-ring/gasket required |

| SAE Straight | Used in hydraulics | Metal-to-metal sealing |

Key Differences:

- NPT vs. BSPT: NPT has a steeper taper; they are not interchangeable.

- BSPP (G-thread) requires a washer/O-ring (common in hydraulics).

Connection & Assembly Process

a) Installation Steps

1. Inspect threads for damage.

2. Apply sealant (Teflon tape for NPT/BSPT, Loctite for high-pressure).

3. Hand-tighten first, then use a wrench (1-2 turns past hand-tight).

4. Avoid over-tightening (can crack fittings).

b) Disassembly

- Threaded fittings can be unscrewed for maintenance (unlike SW/BW).

- Re-sealing may be needed upon reassembly.

Key Differences: Threaded vs. SW vs. BW Fittings

| Feature | Threaded | Socket-Weld (SW) | Butt-Weld (BW) |

| Connection Type | Screwed (NPT/BSP) | Pipe inserted & fillet-welded | Pipe butted & fully welded |

| Pressure Rating | Low-Medium (≤3000 PSI) | High (Up to 9000) | Very High (Unlimited) |

| Leak Resistance | Moderate (sealant needed) | High (welded) | Best (full penetration) |

| Size Range | ⅛" – 12" | ⅛" – 4" | ½" – 48"+ |

| Installation Speed | Fastest (no welding) | Moderate (welding) | Slowest (precision welding) |

| Disassembly | Easy (reusable) | Difficult (cutting) | Permanent (cutting) |

| Cost | Lowest | Medium | Highest |

Applications of Threaded Fittings

✔ Low/Medium Pressure Systems (Water, air, gas).

✔ Plumbing & HVAC (Easy installation).

✔ Maintenance-Friendly Systems (Frequent disassembly needed).

✔ Hydraulic Lines (BSPP/SAE).

Avoid For:

❌ High-pressure steam/oil/gas (risk of leaks).

❌ Vibration-heavy systems (can loosen over time).

❌ Corrosive fluids (unless using stainless steel).

Advantages & Disadvantages

Pros:

- Quick installation (no welding required).

- Reusable & adjustable.

- Cost-effective for small systems.

Cons:

- Not leak-proof under high pressure/vibration.

- Threads can corrode/strip over time.

- Limited to smaller pipes (NPS > 4" is rare).

Conclusion

- Threaded fittings are ideal for low-cost, easy-installation systems where welding is impractical.

- NPT (USA) and BSP (Europe/Asia) are the dominant standards.

- Best for: Water lines, compressed air, hydraulics (BSPP), and maintenance-heavy systems.

- Not recommended for: High-pressure, high-temperature, or corrosive services.

Want to order the same ? Contact us Now to send your request!