Stainless Steel Structure Pipes

Popular Standards

● ASTM A554

● EN10296-2

● GB/T14975

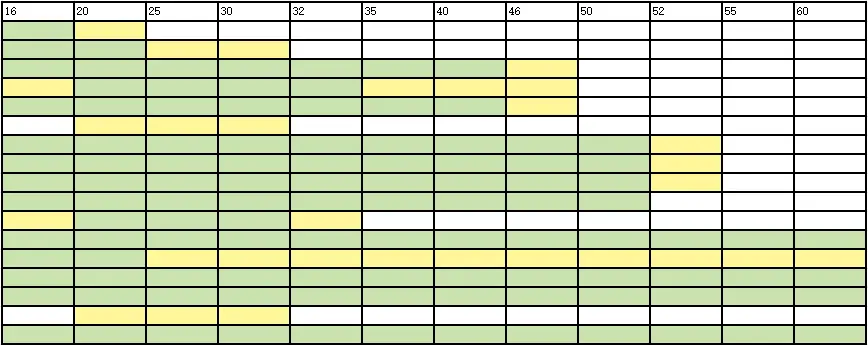

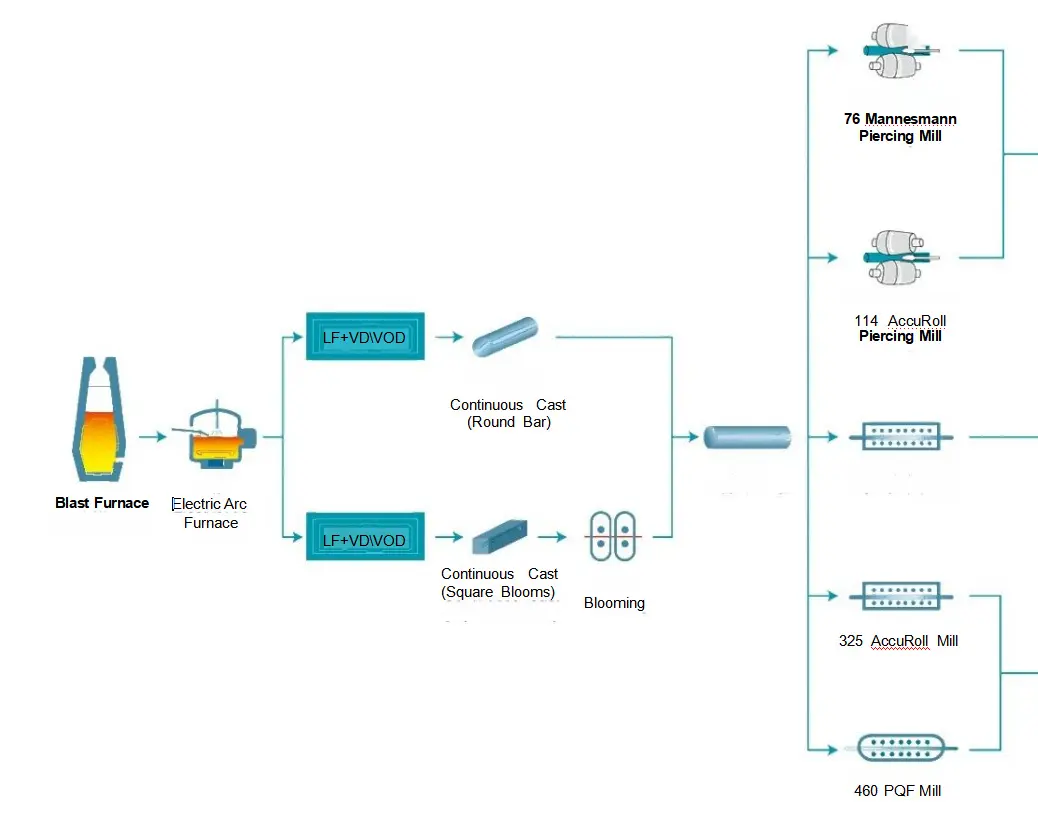

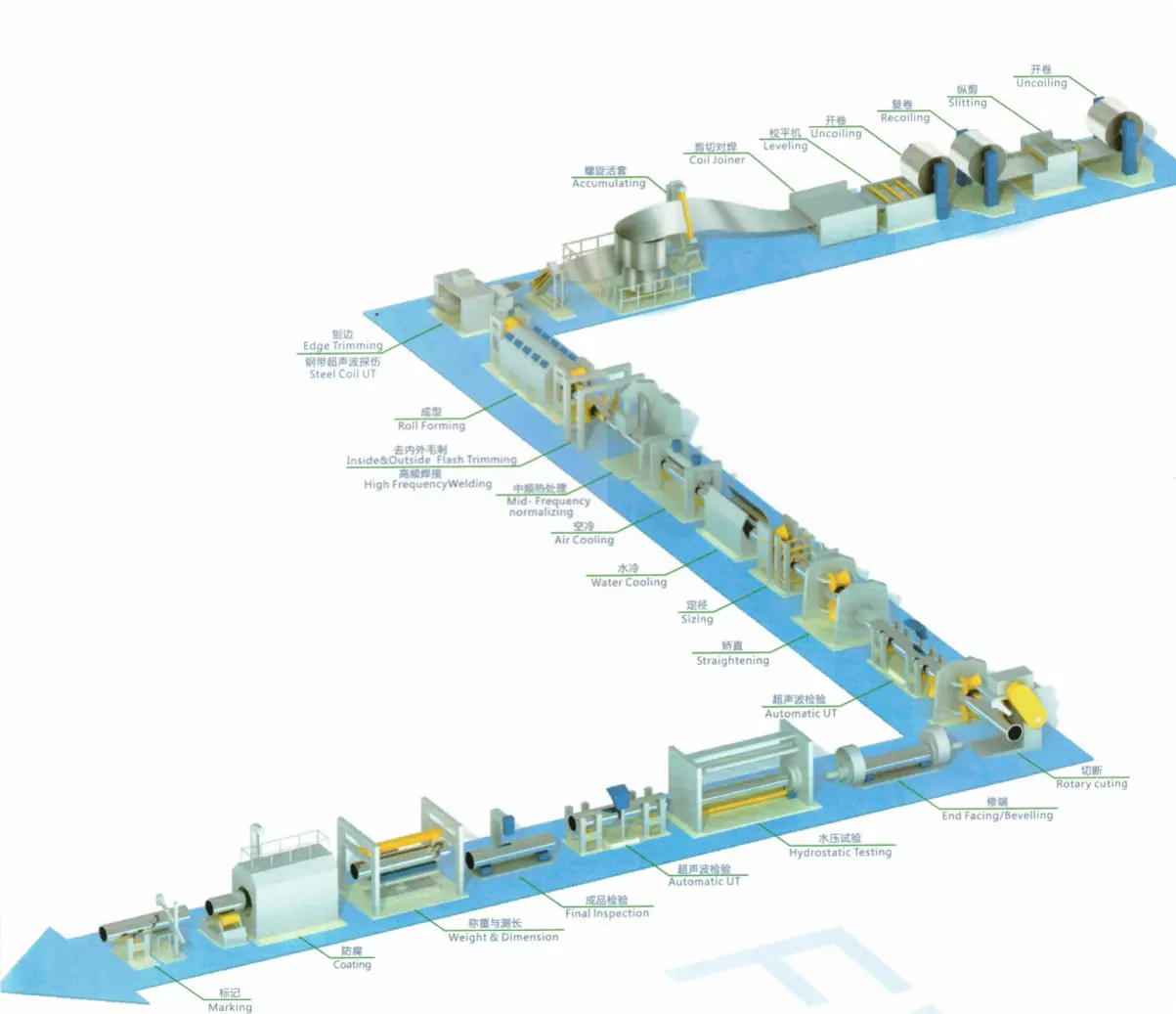

Process Flowchart

Seamless SS Pipe

Welded SS Pipe

Popular Industrial SS Grades

|

Grade |

Type |

C(max) |

Cr |

Ni |

Mo |

Others |

T.S (MPa,max) |

Y.S (MPa,min) |

Elongation (%,min) |

Hardness (HBW) |

| 304 | Austenitic | 0.08 | 18-20 | 8-10.5 | - |

Mn(2%)Si(0.75) |

515 | 205 | 40 | 201 |

| 304L | Austenitic | 0.03 | 18-20 | 8-12 | - | Low carbon | 485 | 170 | 40 | 201 |

| 316 | Austenitic | 0.08 | 16-18 | 10-14 | 2-3 | Improved C/R | 515 | 205 | 40 | 217 |

| 316L | Austenitic | 0.03 | 16-18 | 10-14 | 2-3 | Low carbon | 485 | 170 | 40 | 217 |

| 321 | Austenitic | 0.08 | 17-19 | 9-12 | - | Ti (5x C min) | 515 | 205 | 40 | 201 |

| 347 | Austenitic | 0.08 | 17-19 | 9-13 | - | Nb+Ta | 515 | 205 | 40 | 201 |

| 410 | Martensitic | 0.15 | 11.5-13.5 | - | - | Mn(1%)Si(1%) | 485 | 275 | 20 | 217 |

| 420 | Martensitic | 0.15-0.40 | 12-14 | - | - | High carbon | 586 | 345 | 15 | 235 |

| 430 | Ferritic | 0.12 | 16-18 | - | - | Mn(1%)Si(1%) | 450 | 205 | 22 | 183 |

| 2205 | Duplex | 0.03 | 21-23 | 4.5-6.5 | 2.5-3.5 | N(0.14-0.20%) | 620 | 450 | 25 | 293 |

| 2507 | Duplex | 0.03 | 24-26 | 6-8 | 3-4 | N(0.24-0.32%) | 800 | 550 | 15 | 310 |

Notes:

1. Composition values are in weight % (balance Fe).

2. Mechanical properties are typical values (may vary with heat treatment).

3. Austenitic grades (304, 316) are non-magnetic, corrosion-resistant, and ductile.

4. Martensitic grades (410, 420) are hardenable by heat treatment.

5. Ferritic grades (430) are magnetic with moderate corrosion resistance.

6. Duplex grades (2205, 2507) offer high strength and corrosion resistance.

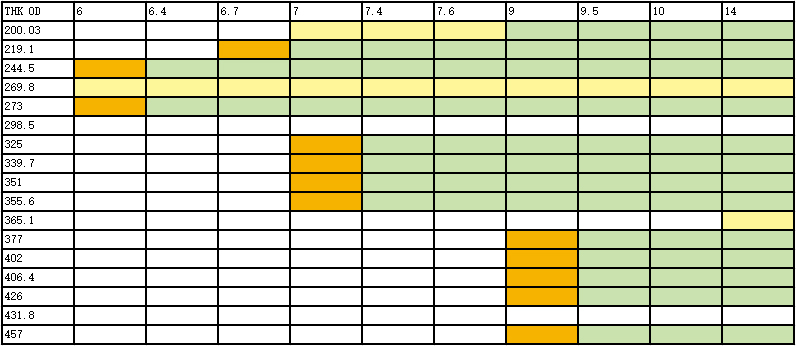

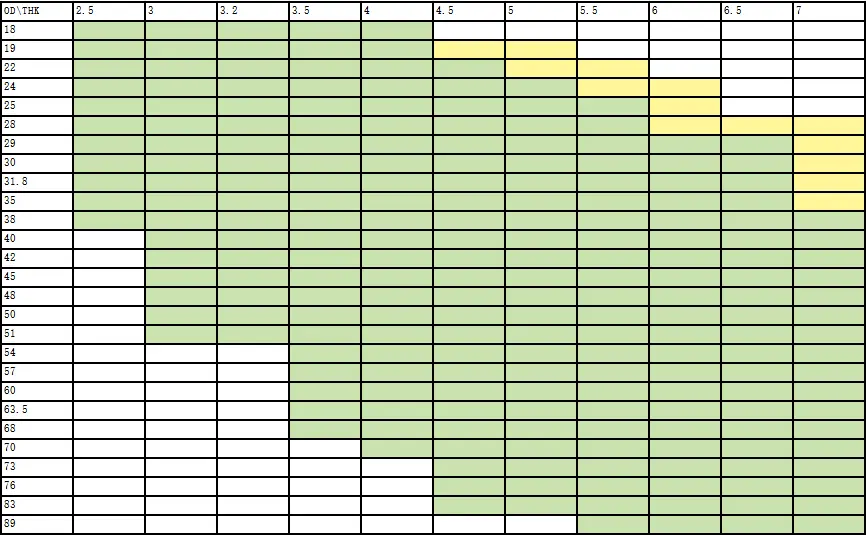

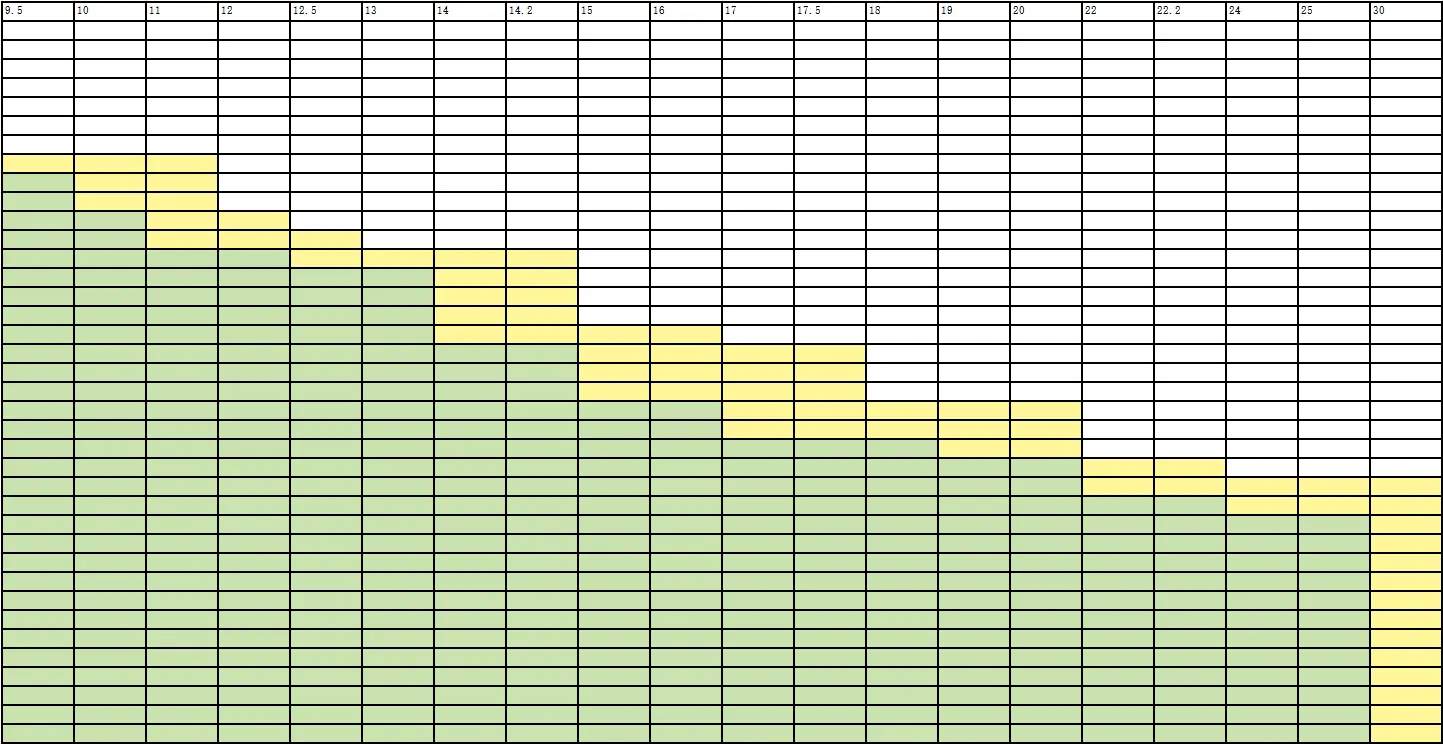

Cold Finished (Cold-drawn or Cold-rolled) Seamless Tube Sizes Available

- Table 01 Unit: MM

- Table to be continued:

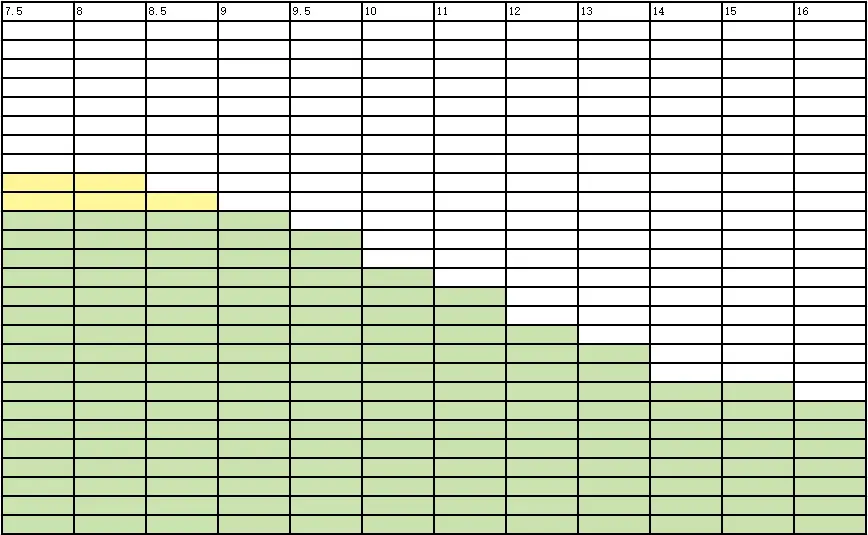

Hot Finished Seamless Pipe Sizes Available

Table 02 Unit: MM

Table 03 Unit: MM

Tolerance on Dimensions

Table 04 Tolerance on Out Diameter Unit: MM

| Standard | Hot Finished Seamless Tube | Cold Finished Seamless Tube | ||

| Outside Diameter (mm) | Tolerance | Outside Diameter (mm) | Tolerance | |

| EN10216-1 EN10216-2 DIN 17175 | ≤100 >100 | ±0.75% (min. ±0.5mm) ±0.90% | All ±0.5% (min. ±0.30mm) | |

| 10~30 ±0.40mm | ||||

| GB/T 3087 | ≤460 | ±0.75% (min. ±0.5mm) | >30~50 ±0.45mm >50 ±1.0% | |

| GB/T 5310 GB/T9948 GB/T6479 | <57 ±0.40mm | ≤30 ±0.20mm | ||

| 57~325 ±0.75% | >30~50 ±0.30mm | |||

| >325~460 +1%,-2mm | >50 ±0.8% | |||

| <25.4 ±0.10mm | ||||

| ASME SA-179M ASME SA-192M ASME SA-209M ASME SA-210M ASME SA-213M | ≤101.6 +0.4,-0.8mm | >25.4~38.1 ±0.15mm | ||

| >38.1~50.8 ±0.20mm | ||||

| >50.8~63.5 ±0.25mm | ||||

| JIS G3461 JIS G3462 | 101.6-190.5 +0.4,-1.2mm | >63.5~76.2 >76.2 | ±0.30mm ±0.38mm | |

| ASME SA-106 ASME SA-335 | ≤48.3 ±0.40mm 48~3-114.3 ±0.79mm 114.4~219.1 +1.59,-0.79mm | ≤48.3 ±0.40mm | ||

| 219.2~323.9 ≥324 | +2.38,-0.79mm ±1.0% | >48.3 ±0.79mm | ||

Table 05 Tolerance on Wall Thickness Unit: MM

|

Standard |

Hot Finished Seamless Tube |

Cold Finished Seamless Tube |

|||

|

Outside Diameter OD(mm) |

Wall Thickness T(mm) |

Tolerance |

Outside Diameter Wall Thickness OD(mm) T(mm) |

Tolerance |

|

| S≤2Sn | +15%,-10% | ||||

| ≤130 | 2Sn<S≤4Sn | +12.5%,-10% | |||

| S>4Sn | ±9% | ||||

| DIN 17175 … … | |||||

| S≤0.05da | +17.5%,-12.5% | ||||

| >130 | 0.05da<S≤0.1lda | ±12.5% | |||

| S>0.1lda | ±10% | All | ±10% (min. ±0.2mm) | ||

| ≤219.1 | ±12.5%(min. ±0.4mm) | ||||

| EN10216-1 EN 10216-2 | T/D≤0.025 | ±20% | |||

| 0.025<T/D≤0.050 | ±15% | ||||

| 0.05<T/D≤0.10 | ±12.5% | ||||

| 0.1<T/D | ±10% | ||||

| GB/T 3087 | ≤20 | +15%,-12.5% (min.+0.45,-0.35mm) | 1.0~3.0 | +15%,-10% | |

| >20 | ±12.5% | >3 | +12.5%,-10% | ||

| GB/T 5310 GB/T 9948 GB/T 6479 | <4.0 | +15%,-10% (min.+0.48,-0.32mm) | 2~3 | +12%,-10% | |

| 4-20 | +12.5%,-10% | >3 | ±10% | ||

| >20 | ±10% | ||||

| ASME SA-179M ASME SA-192M ASME SA-209M ASME SA-210M ASME SA-213M JISG3461 JISG3462 | 2.41-3.8 | +35%,-0% | ≤38.1 | +20%,-0% | |

| 3.8-4.6 | +33%,-0% | >38.1 | +22%,-0% | ||

| >4.6 | +28%,-0% | ---- | |||

| ASME SA-106 ASME SA-335 | All | ±12.5% | All | ±10% | |

For more details on specific carbon and alloy steel tubing and pipes, please refer to the specific product details or contact us at your convenience.