- Carbon & Carbon Alloy Steel

- Stainless Steel

- Copper & Nickel Alloy

- Heat Efficiency Tubes

- Pipe Fittings

- Pipe Flanges

- Gasket, Stud Bolt &Nut

- Industrial Valves

01

Socket-Welding Pipe Fittings for Piping System

Manufacturing Method of SW Fittings

a) Material Selection

- Common materials: Carbon steel (ASTM A105), Stainless steel (ASTM A182 F304/316), Alloy steel (ASTM A182 F11/F22).

- Forged or machined from solid billets for high strength.

b) Forging & Machining Process

1. Hot Forging: Heated metal is shaped under high pressure.

2. Machining:

- Inner socket is precision-machined to fit the pipe snugly.

- Outer surface is finished to meet dimensional standards.

3. Heat Treatment: Annealing or quenching for stress relief.

4. Surface Treatment: Shot blasting, galvanizing (if required).

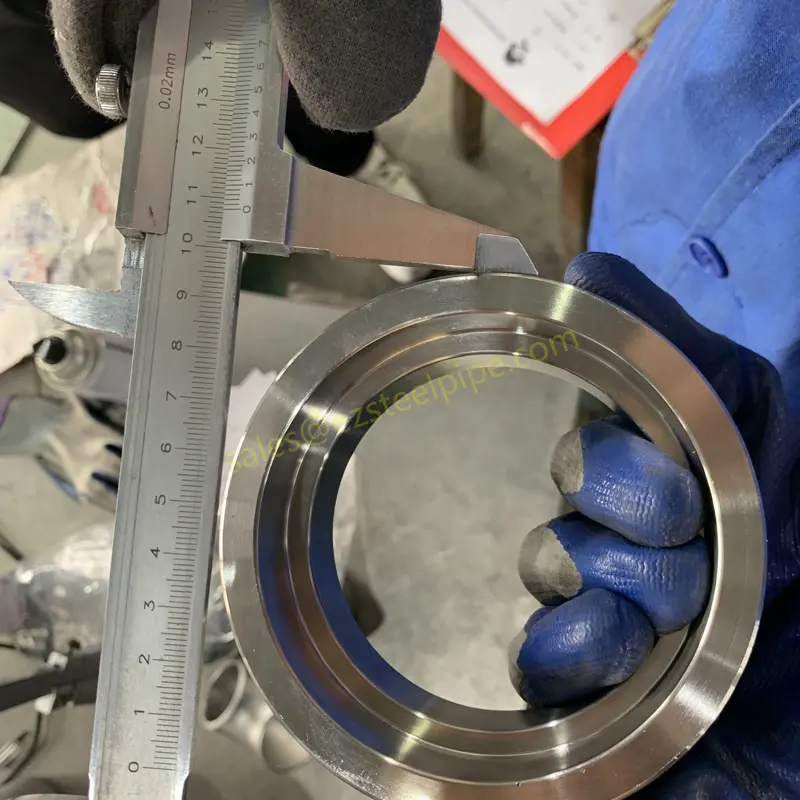

c) Quality Control

- Dimensional checks (per ASME B16.11).

- Pressure testing (optional, depending on application).

- Material certification (MTC as per ASTM/EN).

Common Types of SW Fittings

| Type | Description | Application |

|---------------|----------------|----------------|

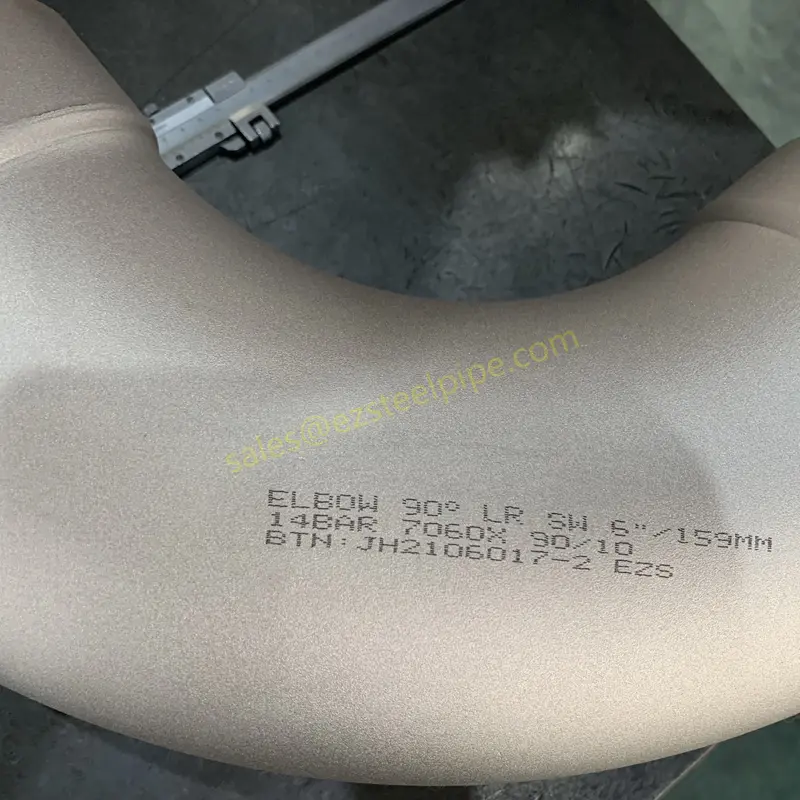

| SW Elbow | 90° or 45° direction change | Compact piping systems |

| SW Tee | Branch connection | Flow splitting/merging |

| SW Coupling | Joins two pipes | Straight pipe connections |

| SW Reducer | Connects different pipe sizes | Pump inlets, valve connections |

| SW Cap | Seals pipe end | System termination |

| SW Union | Allows disassembly | Maintenance points |

Applications of SW Fittings

✔ High-Pressure Systems (Hydraulic lines, steam lines).

✔ Small-Bore Piping (Typically NPS 2" or smaller).

✔ Vibration-Prone Systems (Better resistance than threaded fittings).

✔ Chemical & Petrochemical Plants (Corrosion-resistant SS fittings).

✔ Power Plants & Shipbuilding (High-integrity joints).

Limitations:

❌ Not ideal for large-diameter pipes (NPS > 4").

❌ Slip-on flange alternatives are preferred for frequent disassembly.

Key Differences Between SW and BW Fittings

| Feature | Socket-Weld (SW) | Butt-Weld (BW) |

| Connection Type | Pipe inserted into socket | Pipe welded end-to-end |

| Size Range | NPS ½" to 4" (small bore) | NPS ½" to 48"+ (large bore) |

| Strength | Good for moderate pressure | Superior for high pressure/temperature |

| Internal Flow | Slight restriction at socket | Smooth, uninterrupted flow |

| Welding Process | Fillet weld around joint | Full-penetration groove weld |

| Cost | Lower (less welding prep) | Higher (more labor-intensive) |

| Disassembly | Difficult (welded) | Permanent (cutting required) |

When to Use SW Over BW?

- Small-diameter, high-pressure systems.

- Where space constraints prevent BW flange use.

- When threaded fittings are insufficient.

Popular Manufacturing Standards for SW Fittings

a) ASME B16.11 (Most Common)

- Covers forged carbon/alloy steel SW fittings.

- Pressure ratings: Class 3000, 6000, 9000 (higher than threaded fittings).

- Materials: ASTM A105 (CS), A182 (SS), A350 (low-temp).

b) MSS SP-79 / SP-83

- Stainless steel SW fittings (complements ASME B16.11).

- Used in corrosive environments.

c) EN 10241 / ISO 5251 (European Standards)

- Equivalent to ASME B16.11 but with metric dimensions.

- Common in EU oil & gas, chemical industries.

d) JIS B2306 (Japanese Standard)

- Similar to ASME B16.11 but with JIS material grades.

Installation & Welding Tips for SW Fittings

1. Gap Requirement: Leave a 1.6mm (1/16") gap between pipe and socket shoulder to prevent cracking.

2. Welding Method:

- TIG/GTAW (best for stainless steel).

- SMAW (Stick Welding) for carbon steel.

3. Post-Weld Inspection:

- Visual check for cracks/porosity.

- Dye penetrant testing (PT) for critical systems.

Standard ranges for dimensions, pressure classes, and materials

Socket-welding (SW) fittings are primarily used for small-bore, high-pressure piping systems.

1. Size Range (Nominal Pipe Size – NPS)

| Fitting Type | Common Size Range (NPS) | Max. Typical Size |

| SW Elbow (90°/45°) | ⅛" to 4" | 4" (limited beyond) |

| SW Tee | ⅛" to 4" | 4" |

| SW Coupling | ⅛" to 4" | 4" |

| SW Reducer | ⅛" to 4" | 4" |

| SW Cap | ⅛" to 4" | 4" |

| SW Union | ⅛" to 2" | 2" (rarely beyond) |

Note:

- Most common applications use NPS ½" to 2".

- NPS 3" and 4" are less common (BW fittings preferred).

- NPS > 4" is not standard for SW fittings (butt-welding is used instead).

2. Pressure Class Ratings (ASME B16.11)

SW fittings are classified by pressure ratings, not PN/Class like flanges.

| Pressure Class | Max. Working Pressure (PSI) | Typical Applications |

| Class 3000 | ~750 PSI (51 bar) | General process piping |

| Class 6000 | ~1500 PSI (103 bar) | High-pressure hydraulics |

| Class 9000 | ~2250 PSI (155 bar) | Steam, critical systems |

Key Points:

- Higher class = thicker walls, stronger fittings.

- Class 3000 is most common for standard applications.

- Class 6000/9000 used in oil & gas, power plants.

3. Material Range (Common Standards)

| Material Type | ASTM Standard | Common Grades |

| Carbon Steel | ASTM A105 | A105 (Forged) |

| Stainless Steel | ASTM A182 | F304, F316, F321 |

| Alloy Steel | ASTM A182 | F11, F22, F91 |

| Low-Temp Carbon Steel | ASTM A350 | LF2, LF3 |

4. Comparison with Threaded & Butt-Weld Fittings

| Feature | Socket-Weld (SW) | Threaded (NPT) | Butt-Weld (BW) |

| Size Range | ⅛" – 4" | ⅛" – 12" | ½" – 48"+ |

| Max Pressure | Up to 9000# | Up to 3000# | Unlimited (ASME B16.9) |

| Leak Resistance | Excellent (welded) | Moderate (sealant needed) | Best (full penetration weld) |

| Installation Ease | Moderate (welding skill needed) | Easiest (screw-on) | Most complex (precise welding) |

| Cost | Medium | Lowest | Highest (labor-intensive) |

5. When to Use SW Fittings?

✅ High-pressure, small-bore systems (hydraulics, steam).

✅ Vibration-prone areas (better than threaded).

✅ Where space is limited (compact vs. BW flanges).

❌ Avoid for:

- Large pipes (NPS > 4").

- Systems requiring frequent disassembly (use threaded/unions).

- Highly corrosive fluids (unless using SS grades).

Conclusion

- Standard SW fitting range: ⅛" to 4", with Class 3000, 6000, 9000 pressure ratings.

- Most common materials: A105 (CS), A182 (SS), A350 (low-temp).

- Best for: High-pressure, small-diameter piping where threaded fittings are weak and BW is impractical.

Want to order the same ? Contact us Now to send your request!