Carbon & Alloy Steel Tubes for High Pressure Service

Popular Standards

Chinese Standards

· GB/T 3087 · GB/T9948

· GB/T5310 · GB/T6479

American Society of Mechanical Engineers

| · ASME SA-106M

· ASME SA-179M · ASME SA-192M · ASME SA-209M |

· ASME SA-210M · ASME SA-213M · ASME SA-335M |

- American Society of Testing Materials· ASTMA106M · ASTM A210M· ASTM A179M · ASTM A213M· ASTM A192M · ASTM A335M· ASTMA209M

- European Standards· EN 10216-1 · DIN 17175· EN 10216-2

- Japaneses Industrial Standards· JIS G3461 · JIS G3462

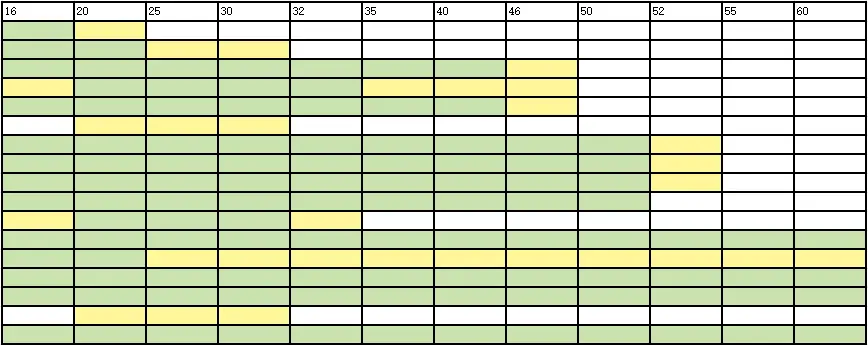

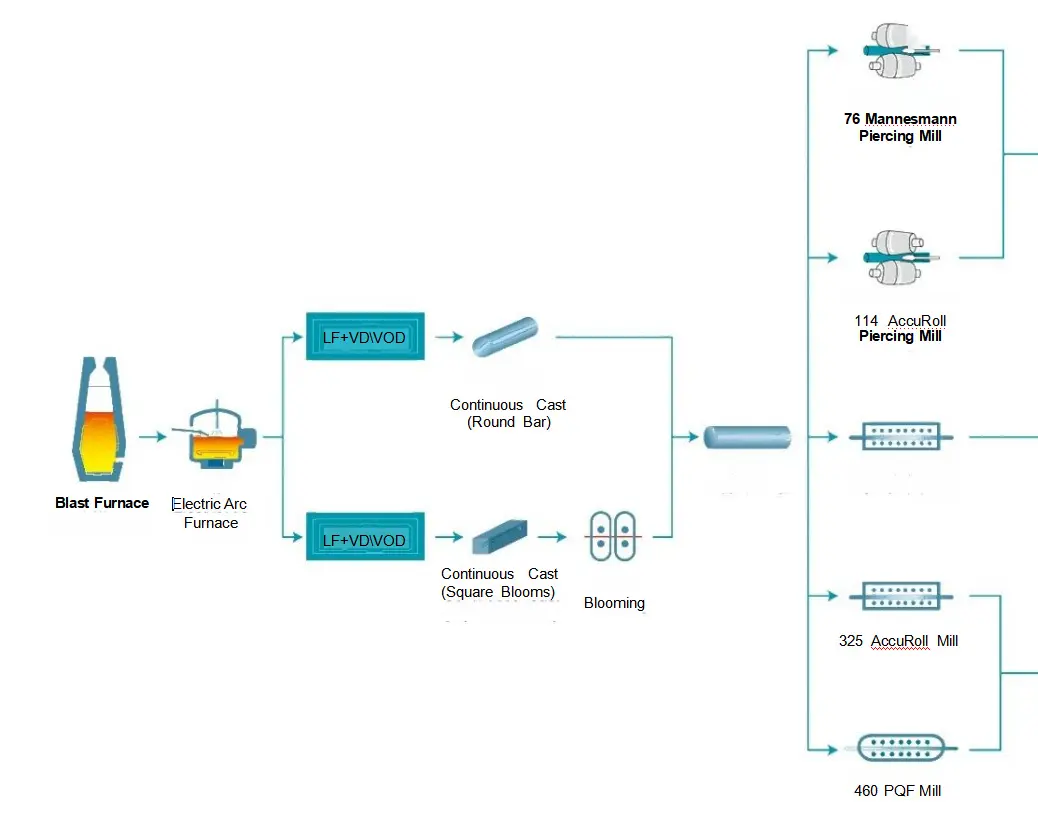

Process Flowchart

Main Product & Applications

| Steel Grade | Standard | Application | |||

| GB | ASTM/ASME | EN/DIN | JIS | ||

| Carbon steel | 10、20 20G 20MnG 25MnG Q345B/C/D/E | A106B SA-106B SA-106C SA-192 SA-210Al SA-210C | St35.8 St45.8 P235GH P265GH | STB340 STB410 STB510 | Economizer tube,

water wall tube,

pipeline,header pipe,

Petrochemical furnace tube, heat exchange tube |

| Mo steel | 15MoG 20MoG | SA-209T1 SA-209Tla SA-209T1b | 16Mo3 | STBA12 STBA13 | Water wall tube superheater tube reheater tube |

| Cr-Mo-V steel | 12Cr1MoVG 12Cr2MoWVTiB | 12Cr1MoV 14MoV63 | Superheater tube,

reheater tube,

pipeline,header pipe,

Petrochemical furnace tube, heat exchange tube |

||

| Cr-Mo steel Cr-Mo-W steel | 12CrMoG 15CrMoG 12Cr2MoG110Cr9Mo1VNbN 10Cr9MoW2VNbBN 12Cr1Mo 12Cr5Mol/NT 12Cr9Mol/NT | T/P11 T/P12 T/P22 T/P23 T/P24 T/P5 T/P9 T/P91 T/P92 | 10CrMo5-5 13CrMo4-5 10CrMo9-10 7CrWVMoNb9-6 7CrMoVTiB10-10 X10CrMoVNb9-1 X10CrWMoVNb9-2 X11CrMo5+l/NT X11CrMo9-1+l/NT | STB20 STB22 STB23 STB24 STB25 STB26 | Superheater tube

reheater tube

main steam pipe,

pipeline,header pipe

Petrochemical furnace tube, heat exchange tube |

| Carbon steel Ni steel | 16MnDG 10MnG 09DG | A333-1 SA-333-1 A333-6 SA-333-6 A333-3 SA-333-3 | STPL380 STPL450 | Tube&pipe for Low-temperature Service | |

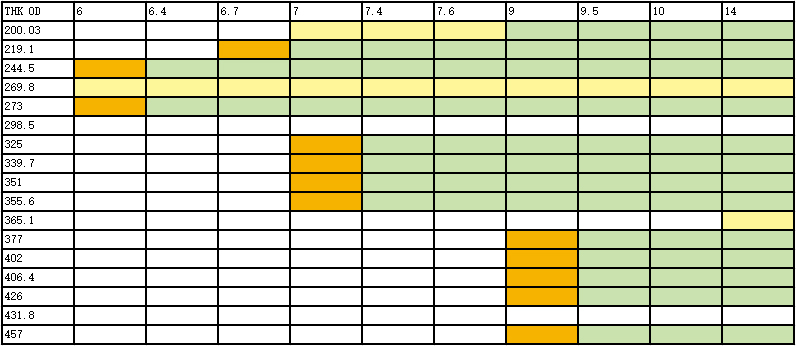

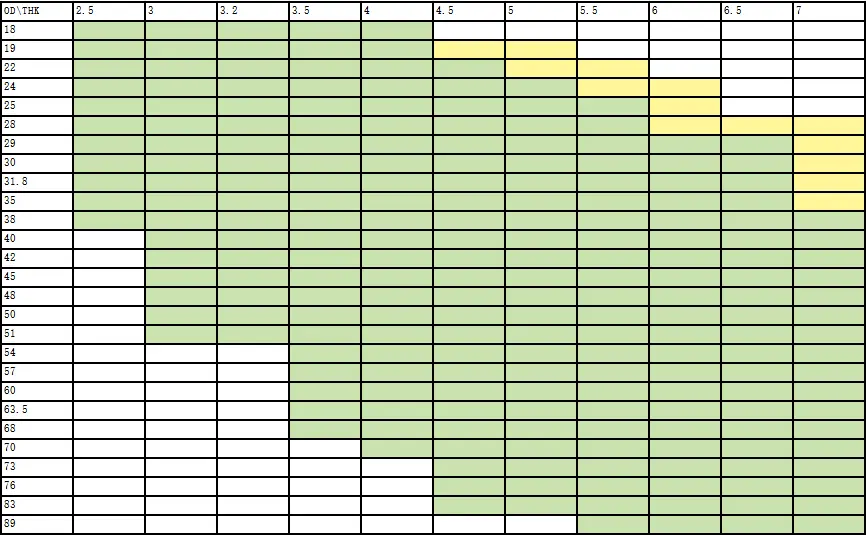

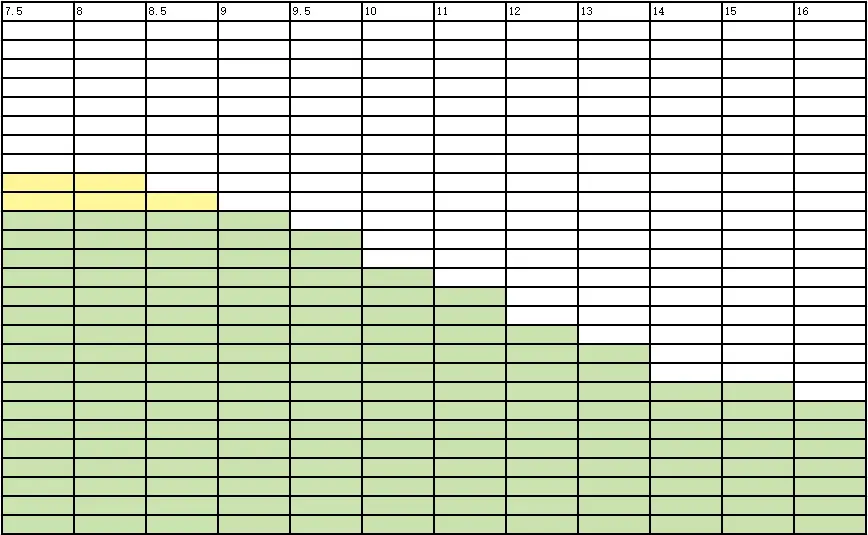

Cold Finished (Cold-drawn or Cold-rolled) Seamless Tube Sizes Available

- Table 01 Unit: MM

- Table to be continued:

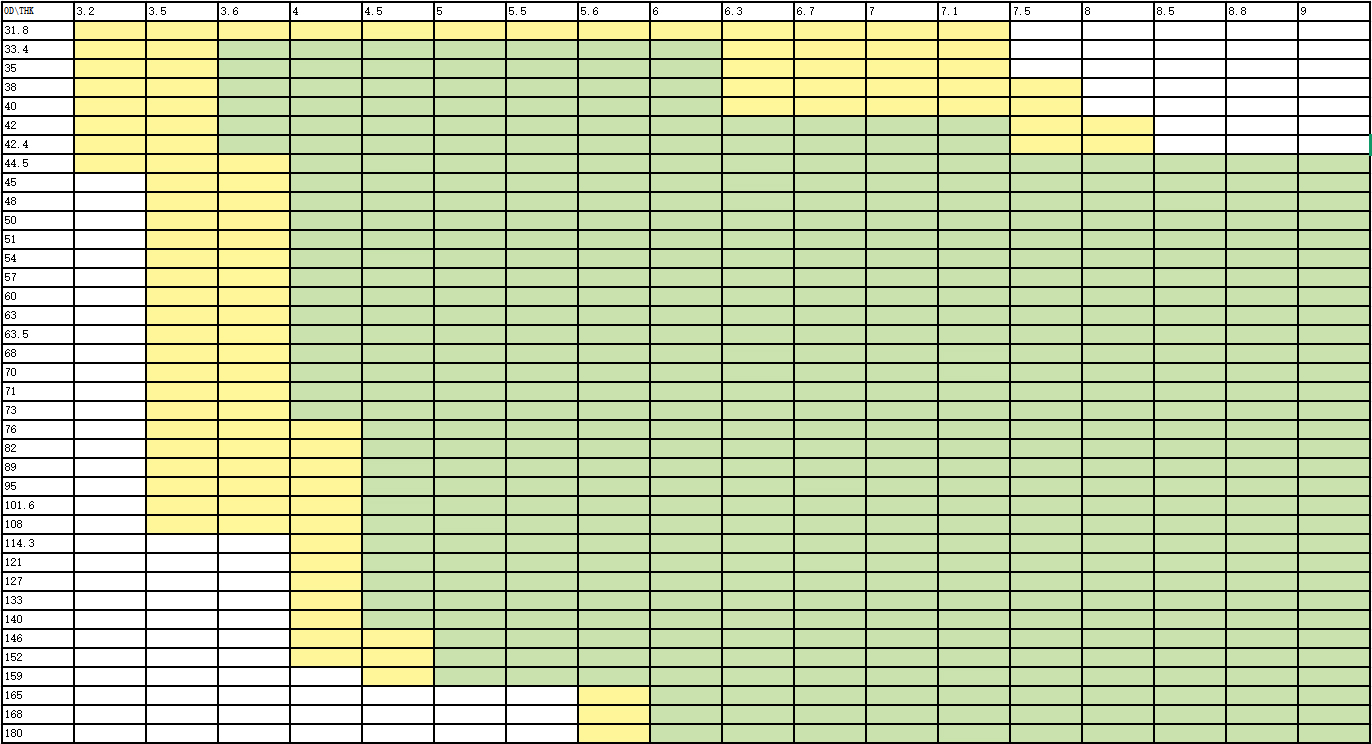

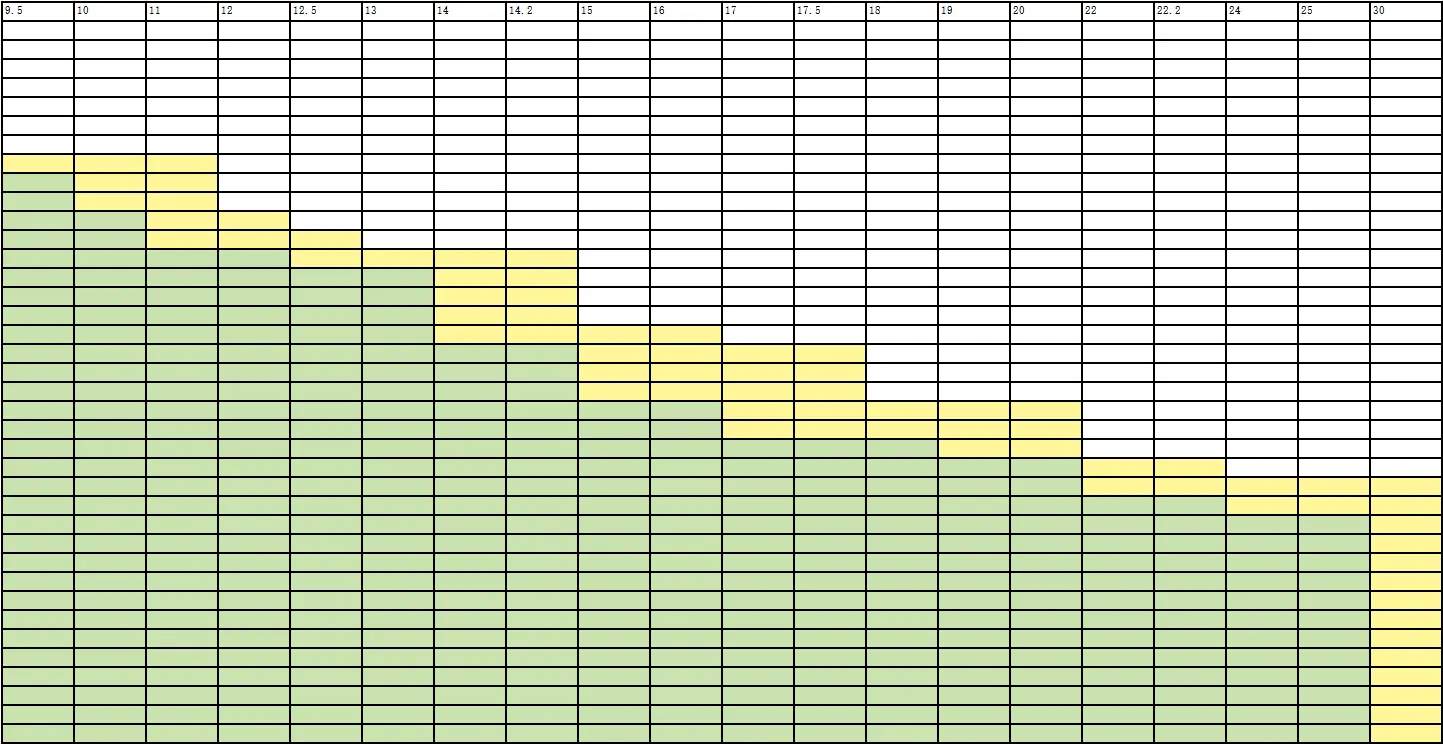

Hot Finished Seamless Pipe Sizes Available

Table 02 Unit: MM

Table 03 Unit: MM

Tolerance on Dimensions

Table 04 Tolerance on Out Diameter Unit: MM

| Standard | Hot Finished Seamless Tube | Cold Finished Seamless Tube | ||

| Outside Diameter (mm) | Tolerance | Outside Diameter (mm) | Tolerance | |

| EN10216-1 EN10216-2 DIN 17175 | ≤100 >100 | ±0.75% (min. ±0.5mm) ±0.90% | All ±0.5% (min. ±0.30mm) | |

| 10~30 ±0.40mm | ||||

| GB/T 3087 | ≤460 | ±0.75% (min. ±0.5mm) | >30~50 ±0.45mm >50 ±1.0% | |

| GB/T 5310 GB/T9948 GB/T6479 | <57 ±0.40mm | ≤30 ±0.20mm | ||

| 57~325 ±0.75% | >30~50 ±0.30mm | |||

| >325~460 +1%,-2mm | >50 ±0.8% | |||

| <25.4 ±0.10mm | ||||

| ASME SA-179M ASME SA-192M ASME SA-209M ASME SA-210M ASME SA-213M | ≤101.6 +0.4,-0.8mm | >25.4~38.1 ±0.15mm | ||

| >38.1~50.8 ±0.20mm | ||||

| >50.8~63.5 ±0.25mm | ||||

| JIS G3461 JIS G3462 | 101.6-190.5 +0.4,-1.2mm | >63.5~76.2 >76.2 | ±0.30mm ±0.38mm | |

| ASME SA-106 ASME SA-335 | ≤48.3 ±0.40mm 48~3-114.3 ±0.79mm 114.4~219.1 +1.59,-0.79mm | ≤48.3 ±0.40mm | ||

| 219.2~323.9 ≥324 | +2.38,-0.79mm ±1.0% | >48.3 ±0.79mm | ||

Table 05 Tolerance on Wall Thickness Unit: MM

|

Standard |

Hot Finished Seamless Tube |

Cold Finished Seamless Tube |

|||

|

Outside Diameter OD(mm) |

Wall Thickness T(mm) |

Tolerance |

Outside Diameter Wall Thickness OD(mm) T(mm) |

Tolerance |

|

| S≤2Sn | +15%,-10% | ||||

| ≤130 | 2Sn<S≤4Sn | +12.5%,-10% | |||

| S>4Sn | ±9% | ||||

| DIN 17175 … … | |||||

| S≤0.05da | +17.5%,-12.5% | ||||

| >130 | 0.05da<S≤0.1lda | ±12.5% | |||

| S>0.1lda | ±10% | All | ±10% (min. ±0.2mm) | ||

| ≤219.1 | ±12.5%(min. ±0.4mm) | ||||

| EN10216-1 EN 10216-2 | T/D≤0.025 | ±20% | |||

| 0.025<T/D≤0.050 | ±15% | ||||

| 0.05<T/D≤0.10 | ±12.5% | ||||

| 0.1<T/D | ±10% | ||||

| GB/T 3087 | ≤20 | +15%,-12.5% (min.+0.45,-0.35mm) | 1.0~3.0 | +15%,-10% | |

| >20 | ±12.5% | >3 | +12.5%,-10% | ||

| GB/T 5310 GB/T 9948 GB/T 6479 | <4.0 | +15%,-10% (min.+0.48,-0.32mm) | 2~3 | +12%,-10% | |

| 4-20 | +12.5%,-10% | >3 | ±10% | ||

| >20 | ±10% | ||||

| ASME SA-179M ASME SA-192M ASME SA-209M ASME SA-210M ASME SA-213M JISG3461 JISG3462 | 2.41-3.8 | +35%,-0% | ≤38.1 | +20%,-0% | |

| 3.8-4.6 | +33%,-0% | >38.1 | +22%,-0% | ||

| >4.6 | +28%,-0% | ---- | |||

| ASME SA-106 ASME SA-335 | All | ±12.5% | All | ±10% | |

For more details on specific carbon and alloy steel tubing and pipes, please refer to the specific product details or contact us at your convenience.