Copper-Nickel Alloy Tubing for Power Plant & Aerospace Works

Popular Standards

● EN1057 ASTM B163

● JIS H3300 RCC-M Section II

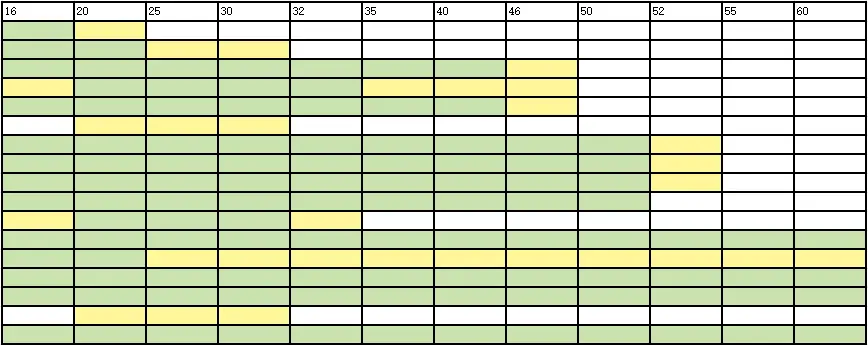

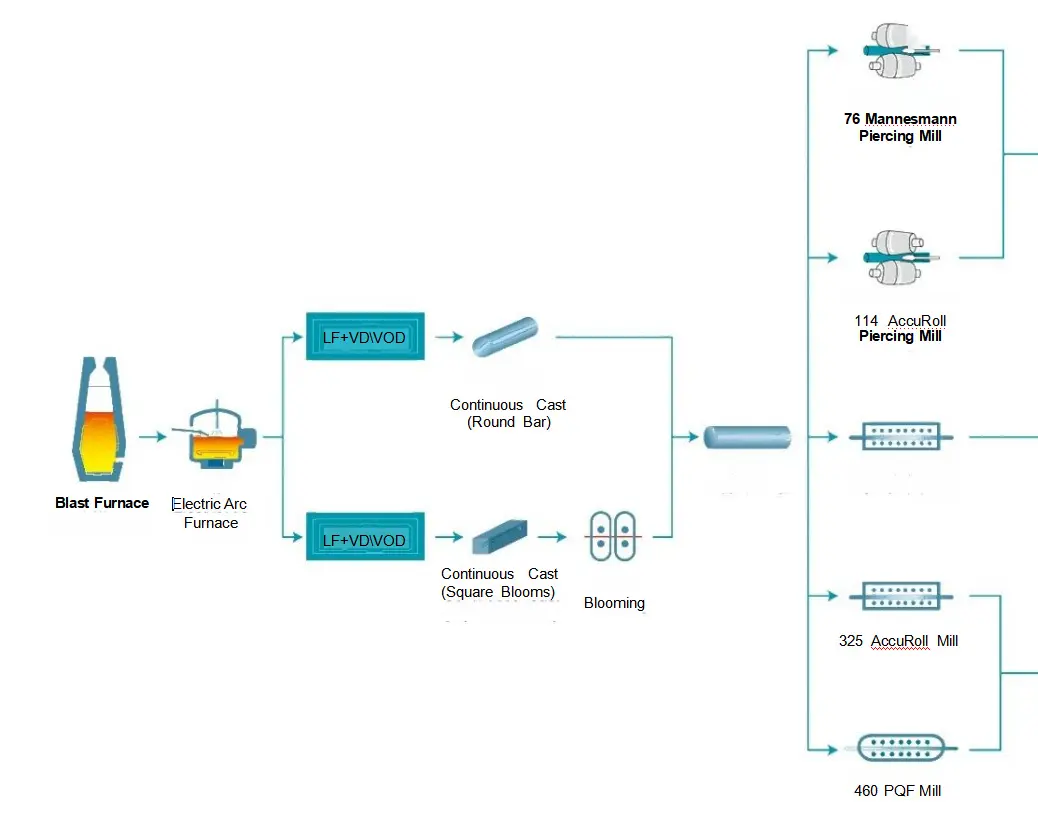

Process Flowchart

Seamless Pipe

Popular Industrial Copper and Nickel Alloy Materials

|

Alloy |

Type |

Composition |

Main Characteristics |

Common Applications |

| C12200 | Phosphorus-Deoxidized Copper | Cu+P (0.015-0.04%) | Excellent Weld-ability, good corrosion resistance, high conductivity | Plumbing, HVAC, piping |

| C44300 | Admiralty Brass | Cu-Zn-Sn + As/Sb | Excellent seawater corrosion resistance, biofouling resistance | Condenser tubes, heat exchangers, marine systems |

| C61400 | Aluminum Bronze | Cu-Al(6-8%)+Fe, Ni | High strength, excellent seawater/erosion resistance, wear-resistant | Marine propellers, pumps, valves, bearings |

| C63000 | Nickel-Aluminum Bronze | Cu-Al-Ni-Fe | Superior corrosion/erosion resistance, high fatigue strength | Aircraft components, heavy-duty marine parts |

| C68700 | Arsenical Aluminum Brass | Cu-Zn-Al-As | Outstanding biofouling/seawater resistance, good formability | Heat exchangers, condensers, desalination plants |

| C70600 | 90-10 Copper-Nickel | Cu-Ni(10%)+Fe/Mn | Excellent seawater corrosion resistance, weldability, moderate strength | Marine piping, offshore platforms, condensers |

| C71500 | 70-30 Copper-Nickel | Cu-Ni(30%)+Fe/Mn | Higher corrosion resistance & strength than C70600, thermal stability | Chemical processing, seawater systems |

| C93200 | High-Lead Tin Bronze | Cu-Sn-Pb | Excellent bearing properties, low friction, machinability | Bushings, bearings, thrust washers |

| Inconel 625 | Nickel-Chromium-Molybdenum | Ni-Cr-Mo-Nb | High strength, oxidation/corrosion resistance (acids/chlorides), fatigue-resistant | Aerospace, chemical procession marine |

| Hastelloy C276 | Nickel-Molybdenum-Chromium | Ni-Mo-Cr-W | Extreme corrosion resistance (HCI,chlorides)stress-corrosion cracking resistant | Chemical reactors,pollution control, oil & gas |

| Monel 400 | Nickel Copper | Ni-Cu(66% Ni,33% Cu) | Excellent resistance to seawater,acids and alkalis, good mechnical strength | Marine engineering, chemical tanks, valves |

| Incoloy 825 | Nickel-Iron-Chromium | Ni-Fe-Cr-Mo-Cu-Ti | Sulfuric/phosphoric acid resistance, high-temperature stability | Chemical processing, acid storage, nuclear |

| Nickel 200 | Pure Nickel | 99.6% Ni | Outstanding corrosion resistance(alkalis,salts),high thermal/ conductivity | Chemical equipment, food processing, electronics |

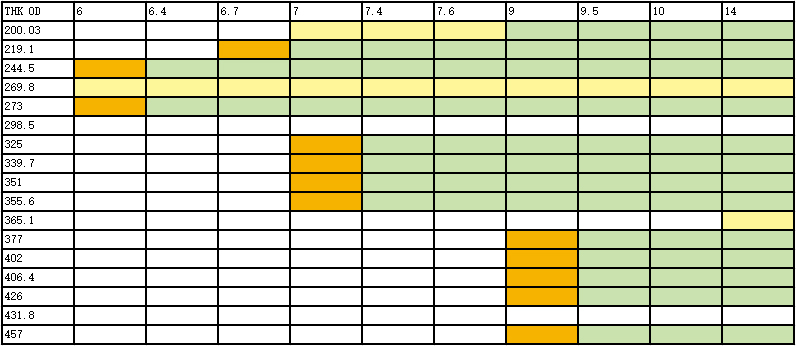

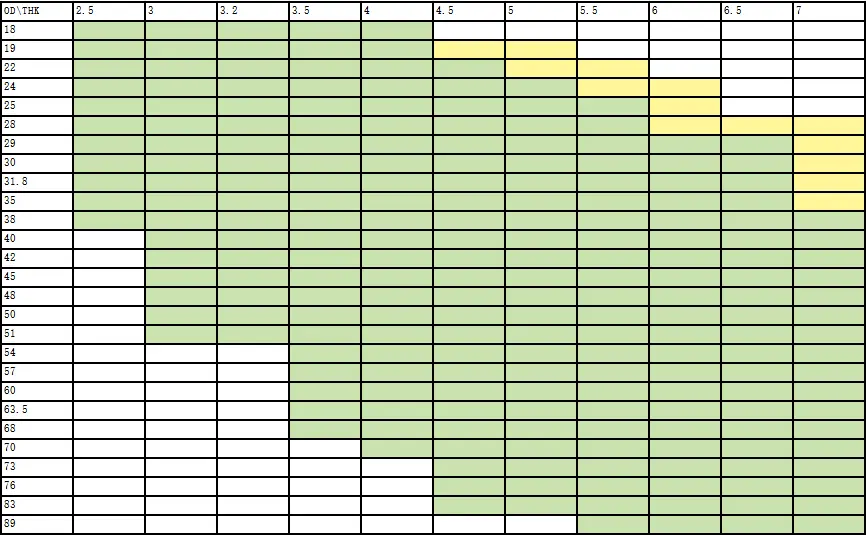

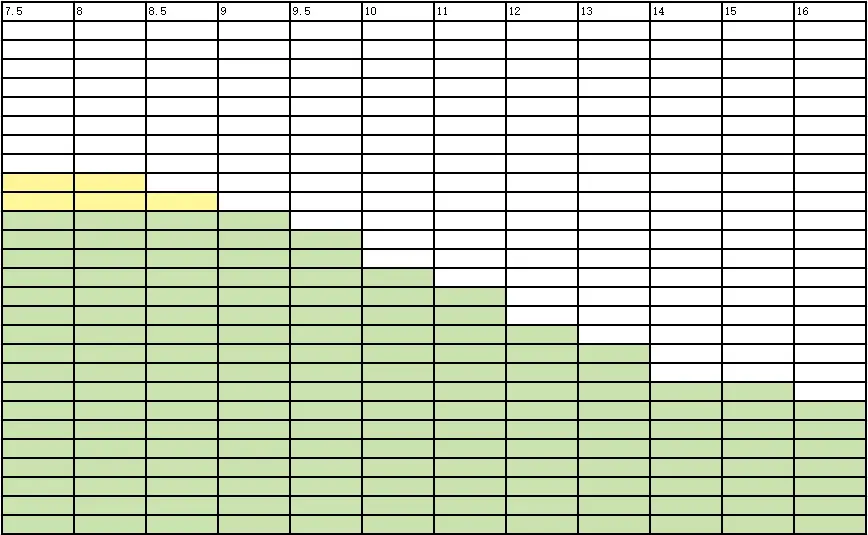

Cold Finished (Cold-drawn or Cold-rolled) Seamless Tube Sizes Available

- Table 01 Unit: MM

- Table to be continued:

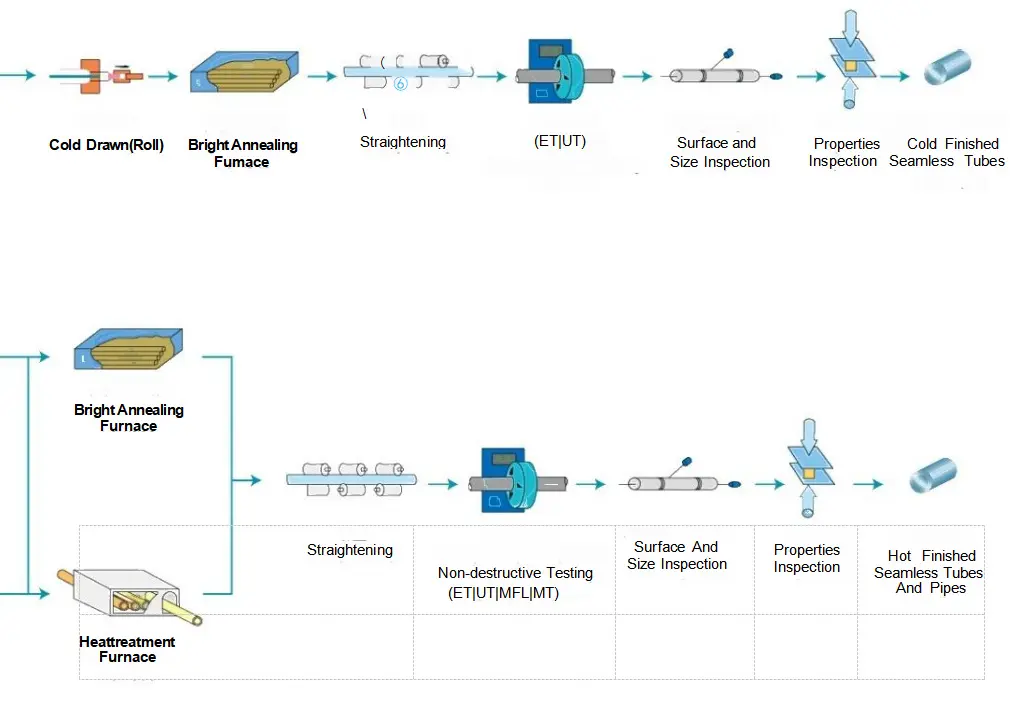

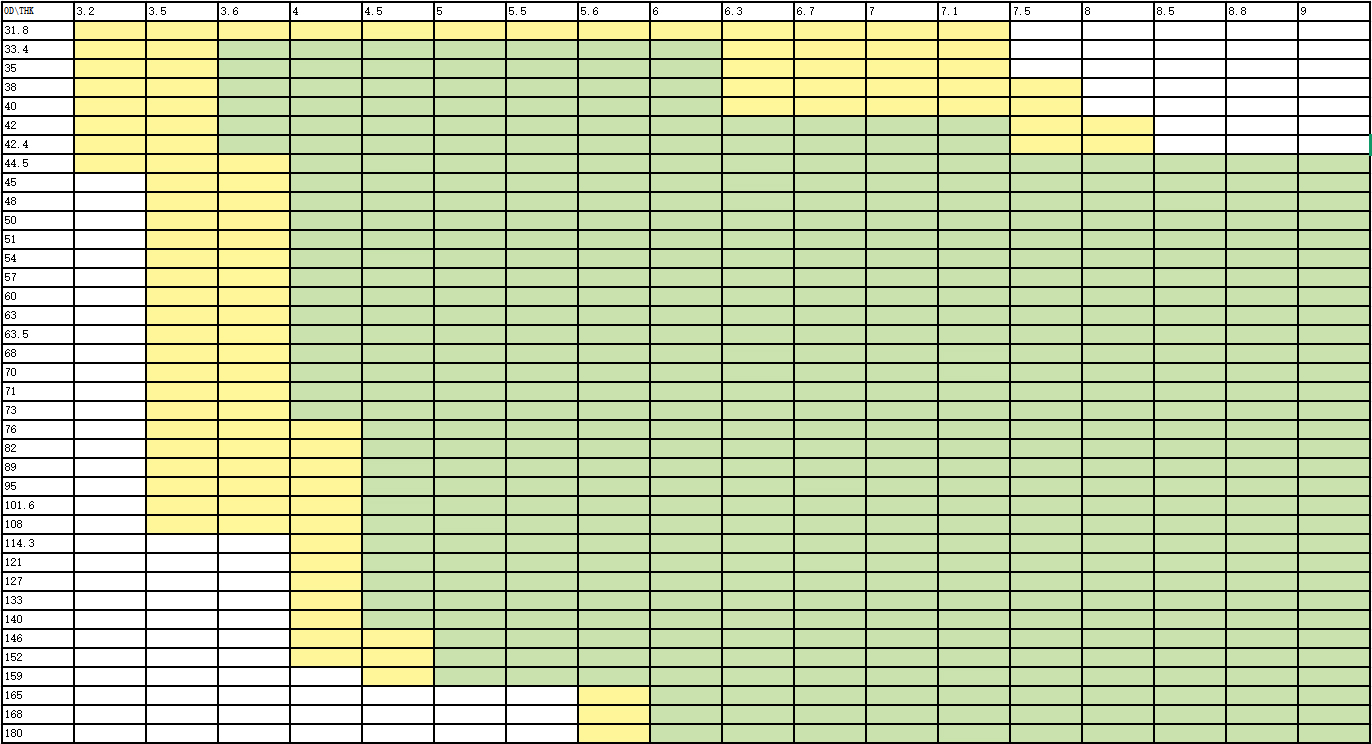

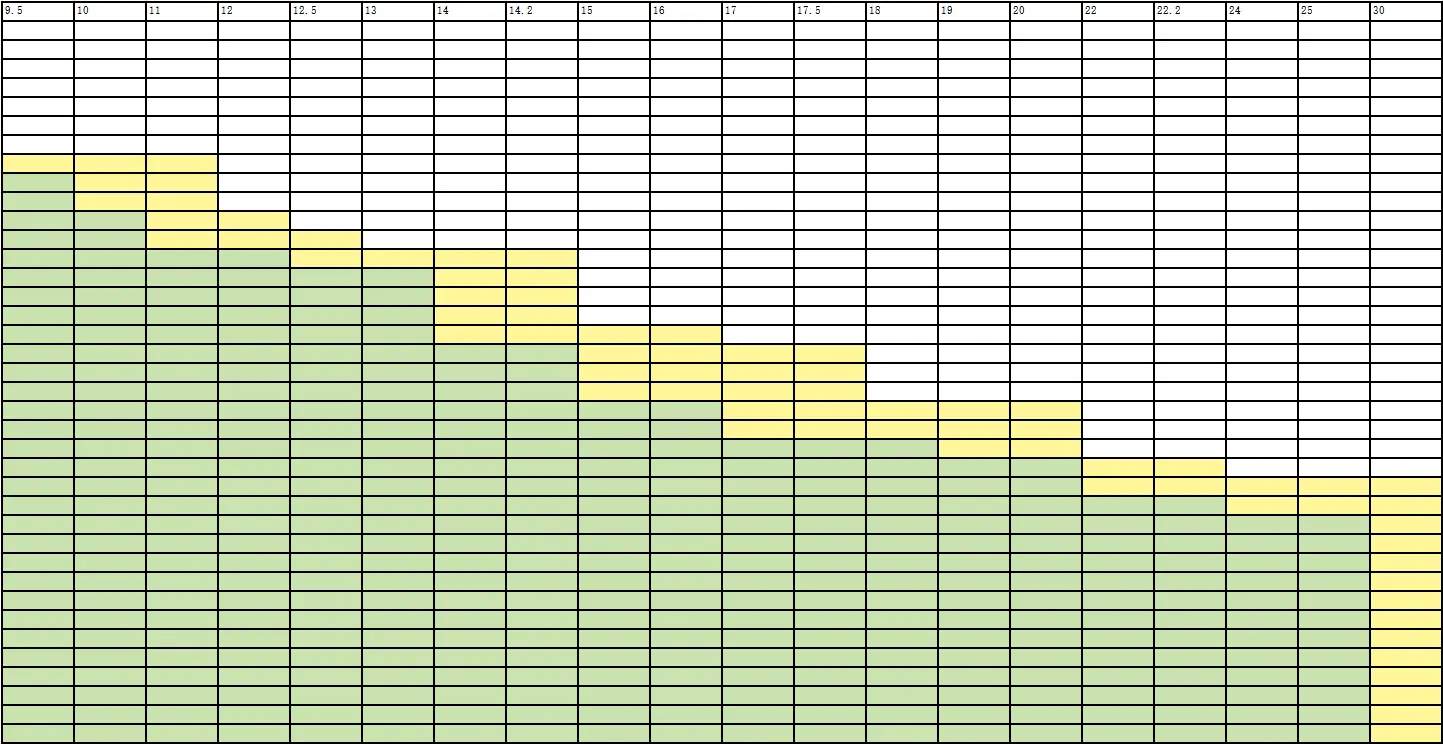

Hot Finished Seamless Pipe Sizes Available

Table 02 Unit: MM

Table 03 Unit: MM

Tolerance on Dimensions

Table 04 Tolerance on Out Diameter Unit: MM

| Standard | Hot Finished Seamless Tube | Cold Finished Seamless Tube | ||

| Outside Diameter (mm) | Tolerance | Outside Diameter (mm) | Tolerance | |

| EN10216-1 EN10216-2 DIN 17175 | ≤100 >100 | ±0.75% (min. ±0.5mm) ±0.90% | All ±0.5% (min. ±0.30mm) | |

| 10~30 ±0.40mm | ||||

| GB/T 3087 | ≤460 | ±0.75% (min. ±0.5mm) | >30~50 ±0.45mm >50 ±1.0% | |

| GB/T 5310 GB/T9948 GB/T6479 | <57 ±0.40mm | ≤30 ±0.20mm | ||

| 57~325 ±0.75% | >30~50 ±0.30mm | |||

| >325~460 +1%,-2mm | >50 ±0.8% | |||

| <25.4 ±0.10mm | ||||

| ASME SA-179M ASME SA-192M ASME SA-209M ASME SA-210M ASME SA-213M | ≤101.6 +0.4,-0.8mm | >25.4~38.1 ±0.15mm | ||

| >38.1~50.8 ±0.20mm | ||||

| >50.8~63.5 ±0.25mm | ||||

| JIS G3461 JIS G3462 | 101.6-190.5 +0.4,-1.2mm | >63.5~76.2 >76.2 | ±0.30mm ±0.38mm | |

| ASME SA-106 ASME SA-335 | ≤48.3 ±0.40mm 48~3-114.3 ±0.79mm 114.4~219.1 +1.59,-0.79mm | ≤48.3 ±0.40mm | ||

| 219.2~323.9 ≥324 | +2.38,-0.79mm ±1.0% | >48.3 ±0.79mm | ||

Table 05 Tolerance on Wall Thickness Unit: MM

|

Standard |

Hot Finished Seamless Tube |

Cold Finished Seamless Tube |

|||

|

Outside Diameter OD(mm) |

Wall Thickness T(mm) |

Tolerance |

Outside Diameter Wall Thickness OD(mm) T(mm) |

Tolerance |

|

| S≤2Sn | +15%,-10% | ||||

| ≤130 | 2Sn<S≤4Sn | +12.5%,-10% | |||

| S>4Sn | ±9% | ||||

| DIN 17175 … … | |||||

| S≤0.05da | +17.5%,-12.5% | ||||

| >130 | 0.05da<S≤0.1lda | ±12.5% | |||

| S>0.1lda | ±10% | All | ±10% (min. ±0.2mm) | ||

| ≤219.1 | ±12.5%(min. ±0.4mm) | ||||

| EN10216-1 EN 10216-2 | T/D≤0.025 | ±20% | |||

| 0.025<T/D≤0.050 | ±15% | ||||

| 0.05<T/D≤0.10 | ±12.5% | ||||

| 0.1<T/D | ±10% | ||||

| GB/T 3087 | ≤20 | +15%,-12.5% (min.+0.45,-0.35mm) | 1.0~3.0 | +15%,-10% | |

| >20 | ±12.5% | >3 | +12.5%,-10% | ||

| GB/T 5310 GB/T 9948 GB/T 6479 | <4.0 | +15%,-10% (min.+0.48,-0.32mm) | 2~3 | +12%,-10% | |

| 4-20 | +12.5%,-10% | >3 | ±10% | ||

| >20 | ±10% | ||||

| ASME SA-179M ASME SA-192M ASME SA-209M ASME SA-210M ASME SA-213M JISG3461 JISG3462 | 2.41-3.8 | +35%,-0% | ≤38.1 | +20%,-0% | |

| 3.8-4.6 | +33%,-0% | >38.1 | +22%,-0% | ||

| >4.6 | +28%,-0% | ---- | |||

| ASME SA-106 ASME SA-335 | All | ±12.5% | All | ±10% | |

For more details on specific carbon and alloy steel tubing and pipes, please refer to the specific product details or contact us at your convenience.