Papua Selatan Sugar Plant Construction: Pipeline Materials Supply and Delivery Progress

Project Background

On June 4, 2024, the Vice President of Indonesia announced that the government would implement a series of measures to develop Papua Selatan Province into a national sugar industry hub. The initiative aims to meet domestic sugar demand and reduce reliance on imports.

Key measures include:

-

Incorporating the sugarcane plantation development plan in the Sermayam area into Indonesia’s National Strategic Projects (PSN);

-

Investing in a processing facility in Sermayam that integrates sugar production and bioethanol processing, scheduled to commence operation in 2027;

-

Supporting the Merauke area to introduce high-quality sugarcane seedlings from Australia, adapted to local climate, temperature, and rainfall conditions, helping plantations achieve a sugar content of over 11%;

-

Cooperating with local educational institutions to provide training programs for sugarcane plantation workers.

-

Business Development

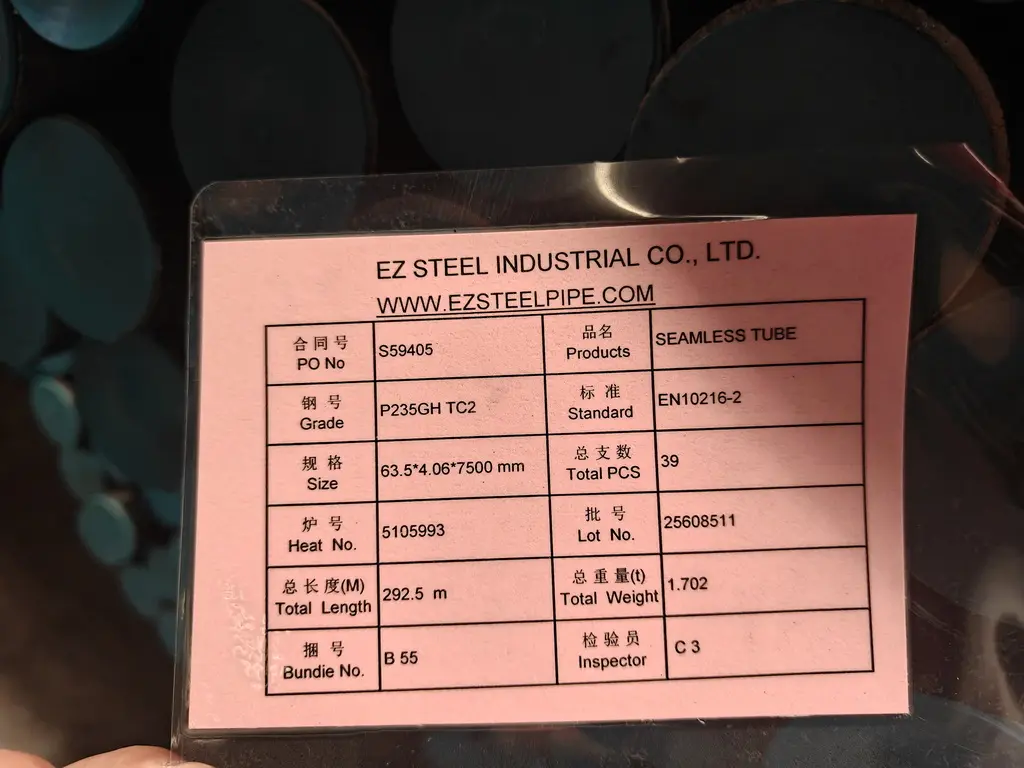

In December 2024, our South African client, JT Company, successfully secured the contract for the first-phase pipeline design, installation, and commissioning package of a sugar plant project in Papua Selatan, Indonesia. After close project tracking and negotiations, in January 2025 our company signed an agreement with JT Company for the supply and fabrication of pipeline materials.

Technical Scope

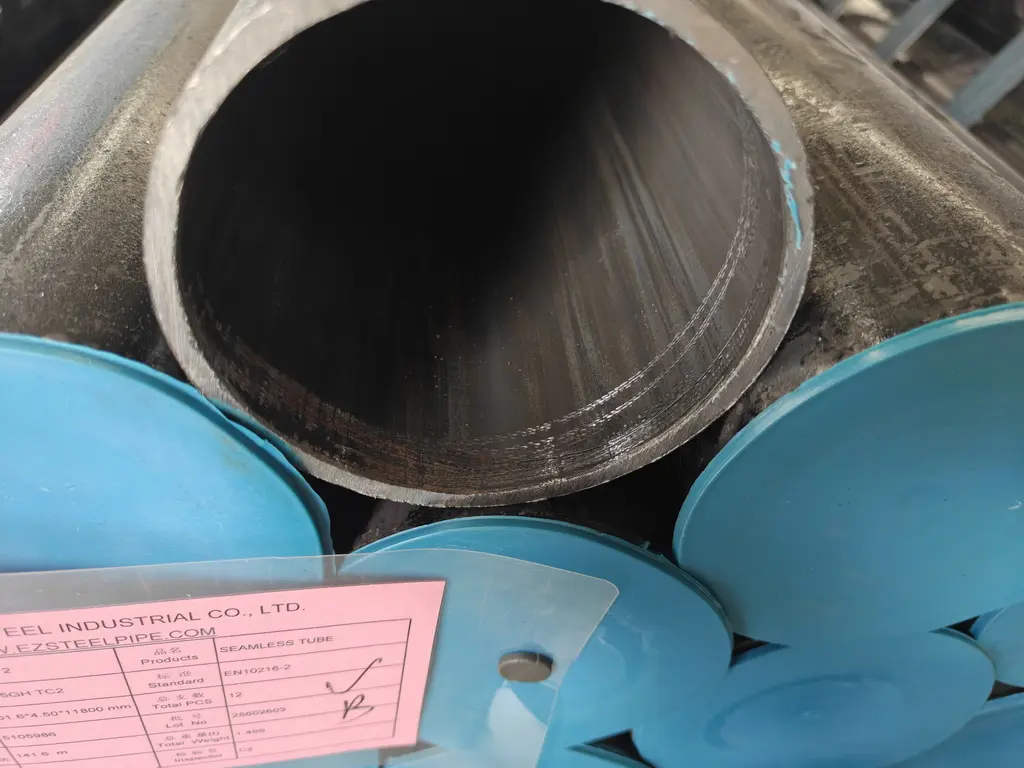

The sugar plant is designed with an annual production capacity of 800,000 tons. Major equipment includes tubular heating boilers, high-pressure steam boilers, high-efficiency crystallization vessels, fermentation units, automatic filtration systems, and supporting pipelines. Internal pipelines are primarily 2-inch to 4-inch in diameter, manufactured from EN10216-2 P235GH TC2, EN10216-2 13CrMo4-5, and ASTM A335 P22 alloy steel pipes. For conveying pipelines, stainless steel ASTM A316L is mainly used.

The first-phase project requires approximately 1,200 tons of metallic pipes and fittings, all designed for high-temperature resistance, high-pressure endurance, and corrosion resistance. To improve manufacturing and installation efficiency, part of the pipeline materials were prefabricated as J-type and U-type pipes, while some large-diameter pipelines required precision mechanical hole processing.

On-Time Delivery

As of August 31, 2025, our company has successfully delivered 721 tons of raw pipes and 102 tons of processed materials, with the remaining quantities scheduled for completion by October 31, 2025. This achievement highlights our reliability as a pipeline materials supplier for sugar plant projects in Indonesia, ensuring both quality and punctual delivery.

About EZ STEEL

As a trusted steel pipes supplier and pipeline solutions provider, EZ STEEL is committed to delivering high-quality products and reliable service for global projects. This successful case in Uruguay once again demonstrates our ability to provide complete pipeline solutions that combine durability, cost-effectiveness, and on-time delivery.