- Carbon & Carbon Alloy Steel

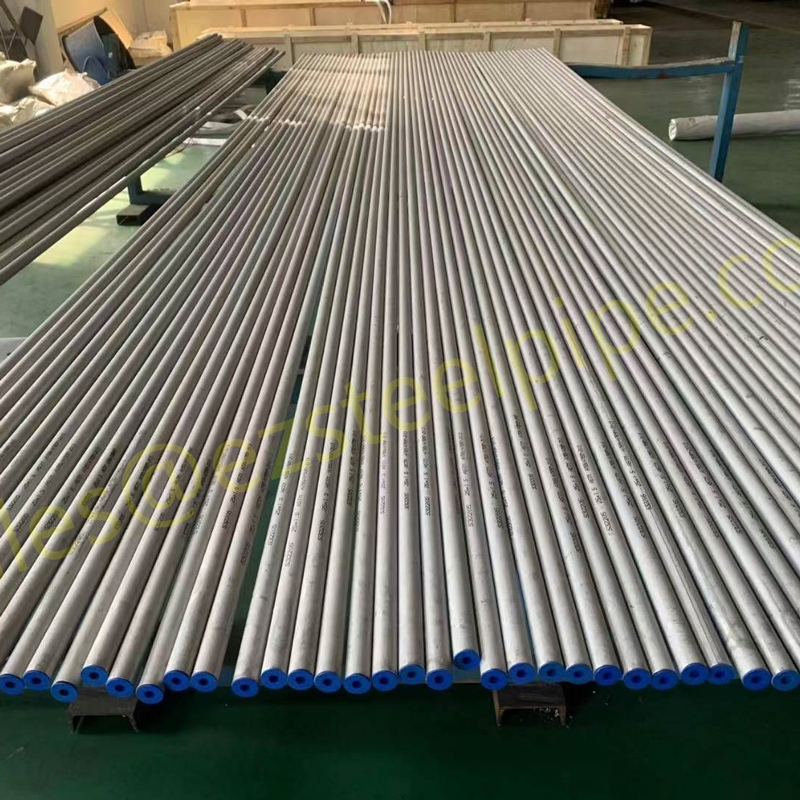

- Stainless Steel

- Copper & Nickel Alloy

- Heat Efficiency Tubes

- Pipe Fittings

- Pipe Flanges

- Gasket, Stud Bolt &Nut

- Industrial Valves

01

JIS H 3300 Standard Specification for Copper and Copper Alloy Seamless Pipes and Tubes

Ordering Information

When ordering, the following details must be specified:

- Standard designation (JIS H 3300)

- Material code (e.g., C1220, C6870)

- Dimensions (outer diameter, wall thickness, length)

- Temper designation (e.g., soft, hard, half-hard)

- Quantity

- Special requirements (e.g., surface finish, end treatment)

Material Codes and Alloys

Common material codes include:

- C1020 (Oxygen-free copper)

- C1220 (Phosphorus-deoxidized copper)

- C2801 (Brass: 60% Cu, 40% Zn)

- C4430, C6870 (Aluminum brass, Arsenic-added brass)

- C7060, C7150 (Copper-nickel alloys)

Each material has specified chemical composition limits per JIS H 3300.

Manufacturing Process

- Pipes/tubes are produced by extrusion, cold drawing, or rolling.

- Heat treatment (annealing) may be applied to achieve desired temper.

Dimensions and Tolerances

- Standard outer diameters, wall thicknesses, and lengths are specified.

- Tolerances for dimensions (OD, WT, straightness, etc.) are defined based on material and temper.

Mechanical Properties

- Tensile strength, elongation, and hardness requirements vary by material and temper.

- Example:

- C1220 (Soft) – Tensile strength ≥ 200 MPa, Elongation ≥ 40%

- C2801 (Hard) – Tensile strength ≥ 370 MPa, Elongation ≥ 15%

Inspection Requirements

- Chemical analysis (to verify composition).

- Mechanical tests (tensile, hardness).

- Hydrostatic or nondestructive testing (e.g., eddy current) for leak tightness.

- Visual inspection (surface defects, scratches, dents).

- Dimensional checks (OD, WT, length).

Surface Condition

- Surfaces must be clean, free from cracks, and excessive imperfections.

- Minor scratches or discoloration may be allowed within limits.

Marking and Packaging

- Each pipe/tube must be marked with:

- Manufacturer’s name or trademark.

- Material code.

- Dimensions.

- Heat number/batch identification.

- Packaging must prevent damage during transit.

Material Codes in JIS H 3300

1. Pure Copper (Copper ≥ 99.90%)

- C1020 (Oxygen-free copper)

- C1100 (Electrolytic tough pitch copper, Cu ≥ 99.90%)

- C1220 (Phosphorus-deoxidized copper, Cu + Ag ≥ 99.90%)

2. Brass (Copper-Zinc Alloys)

- C2100 (95% Copper Brass, Cu 84–86%, remainder Zn)

- C2200 (90% Copper Brass, Cu 88–91%, remainder Zn)

- C2300 (85% Copper Brass, Cu 84–86%, remainder Zn)

- C2400 (80% Copper Brass, Cu 78.5–81.5%, remainder Zn)

- C2600 (70% Copper Brass, Cu 68.5–71.5%, remainder Zn)

- C2680 (Yellow Brass, Cu 64–68%, remainder Zn)

- C2700 (65% Copper Brass, Cu 63–68.5%, remainder Zn)

- C2720 (Common Brass, Cu 62–64%, remainder Zn)

- C2801 (60% Copper Brass, Cu 58–61%, remainder Zn)

3. Leaded Brass (Free-Cutting Brass)

- C3140 (Leaded Brass, Cu 87–90%, Pb 1.3–2.5%, remainder Zn)

- C3501 (Leaded Brass, Cu 60–63%, Pb 1.3–2.5%, remainder Zn)

- C3604 (Free-Cutting Brass, Cu 57–61%, Pb 1.8–3.7%, remainder Zn)

4. Tin Brass & Special Brass

- C4430 (Admiralty Brass, Cu 70–73%, Sn 0.8–1.2%, Zn + As remainder)

- C4621 (Naval Brass, Cu 60–63%, Sn 0.5–1.0%, Pb ≤ 0.2%, remainder Zn)

- C6870 (Aluminum Brass, Cu 76–79%, Al 1.8–2.5%, As 0.02–0.06%, remainder Zn)

5. Copper-Nickel Alloys

- C7060 (90-10 Cu-Ni, Cu 86.5–90.5%, Ni 9–11%, Fe 1–1.8%, Mn ≤ 1.0%)

- C7150 (70-30 Cu-Ni, Cu 63–70%, Ni 29–33%, Fe 0.4–1.0%, Mn ≤ 1.0%)

6. Other Copper Alloys

- C5111 (Phosphor Bronze, Cu + Sn 99.5%, P 0.03–0.35%)

- C5191 (Phosphor Bronze, Cu 93.5–95.5%, Sn 6–7%, P 0.1–0.25%)

- C7060, C7150 (Copper-Nickel, as above)

Key Notes:

- The exact chemical composition limits are specified in JIS H 3300.

- Some alloys may have additional restrictions on impurities (e.g., Pb, Fe, Ni).

- Temper designations (e.g., soft, hard, half-hard) affect mechanical properties.

Want to order the same ? Contact us Now to send your request!