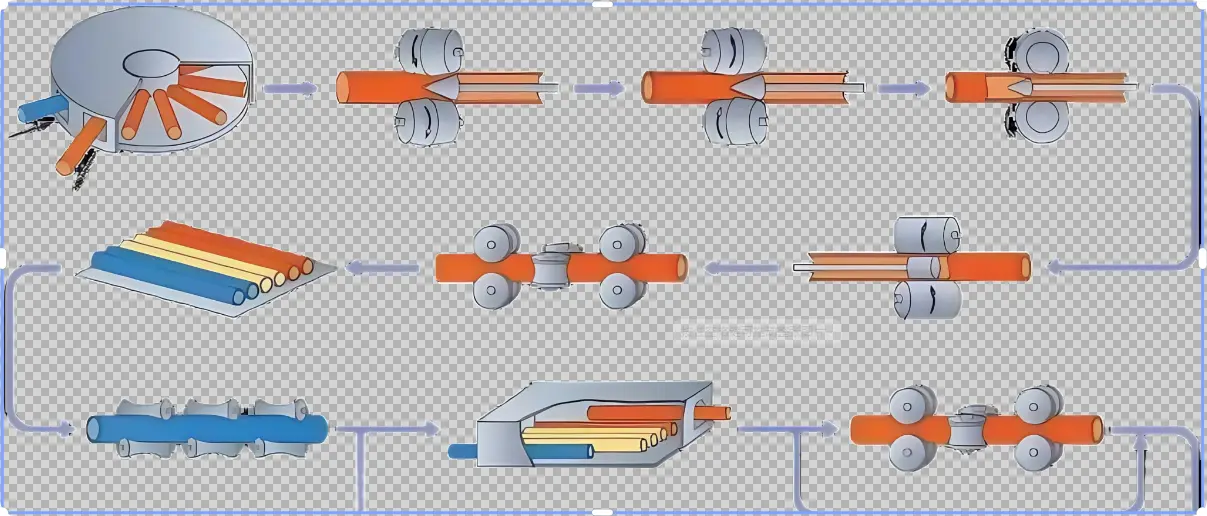

How to make a hot-finished seamless pipe ?

The production of hot-finished seamless pipes involves several key steps, from heating steel billets to forming and finishing the pipes. Below is a detailed step-by-step process:

---

1. Raw Material Preparation

- Steel Billets: Round solid steel billets (continuous cast or hot-rolled) are selected based on the desired pipe grade (e.g., carbon steel, alloy steel, stainless steel).

- Inspection: Billets are checked for surface defects (cracks, voids) and chemical composition.

---

2. Heating the Billet

- Furnace Heating: Billets are heated in a rotary hearth furnace or induction furnace to 1200–1300°C (2192–2372°F) to make them malleable for piercing.

- Temperature Control: Precise heating ensures uniformity to avoid cracks during forming.

---

3. Piercing (Hot Piercing Mill)

- Mandrel Mill or Rotary Piercer: The heated billet is fed into a piercing mill, where a piercing plug (mandrel) and rollers create a hollow shell (called a "hollow bloom" or "mother tube").

- Process: The billet is cross-rolled and stretched over the mandrel to form a thick-walled tube.

---

4. Elongation (Rolling Process)

- Mandrel Mill or Plug Mill: The hollow shell is elongated using a series of tapered rolls and a mandrel to reduce wall thickness and increase length.

- Stretch Reduction Mill (Optional): Some mills use additional rolling stands to further refine dimensions.

---

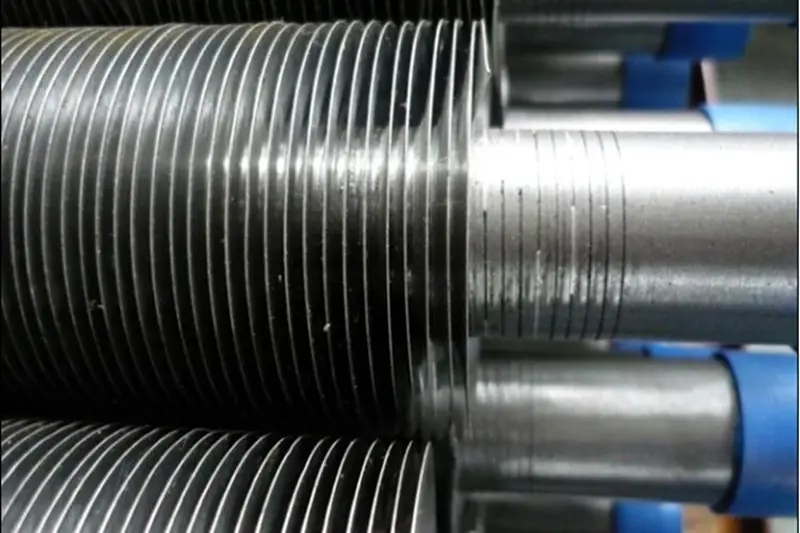

5. Sizing and Reeling

- Sizing Mill: The pipe passes through a series of stands with grooved rolls to achieve the final outer diameter (OD) with tight tolerances.

- Reeling (Optional): Improves roundness and surface finish by lightly rolling the pipe.

---

6. Cooling

- Cooling Bed: The hot pipe is transferred to a cooling bed and air-cooled or controlled cooled (for specific metallurgical properties).

---

7. Straightening & Cutting

- Straightening: The pipe passes through a rotary straightening machine to correct any bends or deformations.

- Cutting: Pipes are cut to specified lengths using a saw or torch.

---

8. Heat Treatment (If Required)

- Annealing/Normalizing/Quenching & Tempering: Applied for pipes requiring specific mechanical properties (e.g., high-pressure applications).

---

9. Finishing & Inspection

- Surface Treatment:

- Shot blasting removes scale.

- Phosphating/oiling prevents corrosion.

- Non-Destructive Testing (NDT):

- Ultrasonic Testing (UT) for internal defects.

- Eddy Current Testing (ECT) for surface cracks.

- Hydrostatic Testing for pressure resistance.

- Dimensional Checks: OD, wall thickness, length, and straightness are verified.

---

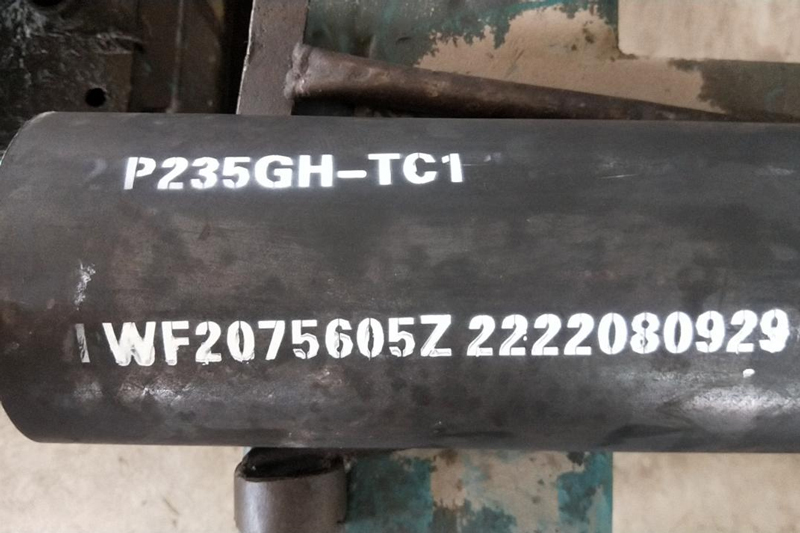

10. Final Processing & Dispatch

- End Facing/Beveling (If Needed): For welding-ready pipes.

- Marking & Coating: Pipes are marked with grade, size, and manufacturer details.

- Packaging & Shipping: Pipes are bundled and shipped to customers.

---

Key Hot-Finished Seamless Pipe Mills

- Mandrel Mill Process (Most common for medium-sized pipes)

- Plug Mill Process (For thicker walls)

- Assel Mill (For precision pipes)

---

- Advantages of Hot-Finished Seamless Pipes- Superior strength & pressure resistance.- Uniform microstructure (no welds).- Suitable for high-temperature/pressure applications (oil & gas, power plants, boilers).