ERW (electric resistance welded) and hfw (high-frequency welded) steel pipes manufacturing

Manufacturing ERW (Electric Resistance Welded) and HFW (High-Frequency Welded) steel pipes from steel coils involves a series of precise steps to form, weld, and finish the pipes. Here’s a step-by-step introduction to the process:

- 1. Material Preparation (Uncoiling & Leveling)- Steel coils are loaded onto an uncoiler and fed into the production line.- The strip passes through a leveling machine to ensure flatness and remove any deformations.2. Edge Trimming (Optional)- If needed, the edges of the strip are trimmed to ensure uniform width and smooth welding surfaces.

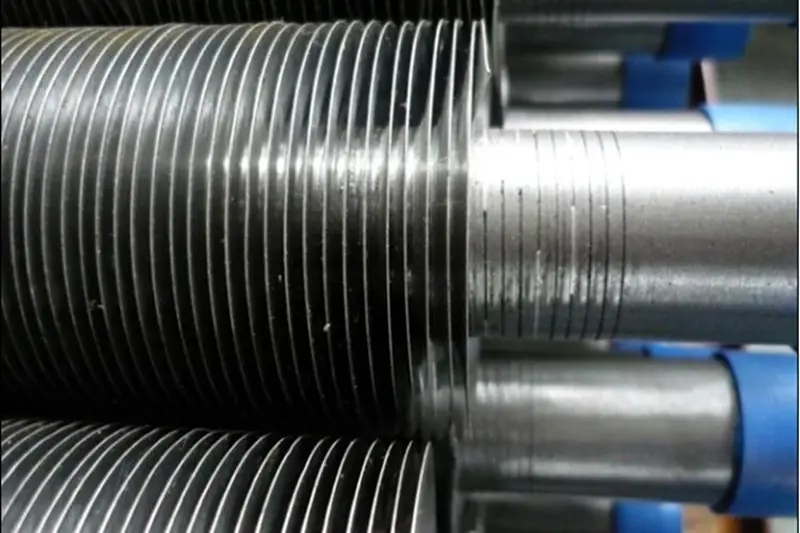

3. Forming Process

- The flat strip is gradually formed into a cylindrical shape using a series of forming rolls (cage rollers).

- Common forming methods:

- Butt-Welding (ERW): The edges meet but are not overlapped.

- Lap-Welding (for thicker pipes): The edges overlap before welding.

4. High-Frequency Welding (ERW/HFW)

- The open edges are heated using high-frequency induction (HFI) or high-frequency contact (HFC) welding.

- Pressure is applied to forge the edges together without filler metal.

- The weld is instantly solidified, forming a seamless bond.

5. Weld Flash Removal

- The excess weld bead (flash) is trimmed off using an internal/external scarfing tool to ensure a smooth surface.

6. Sizing & Shaping

- The welded pipe passes through sizing rolls to achieve the exact diameter and roundness.

7. Cooling

- The pipe is cooled using water or air to stabilize the weld zone and microstructure.

8. Straightening & Cutting

- The pipe is straightened using multi-roll straightening machines.

- It is then cut to the required length using a flying saw or hydraulic cutter.

9. Inspection & Testing

- Visual Inspection: Checks for surface defects.

- Non-Destructive Testing (NDT): Ultrasonic (UT), Eddy Current (ET), or Hydrostatic testing to ensure weld integrity.

- Dimensional Checks: Diameter, wall thickness, and straightness verification.

10. End Facing & Beveling (Optional)

- Pipe ends are machined for smoothness or beveled for welding compatibility.

11. Surface Treatment & Coating (Optional)

- Pipes may be galvanized, painted, or coated for corrosion resistance.

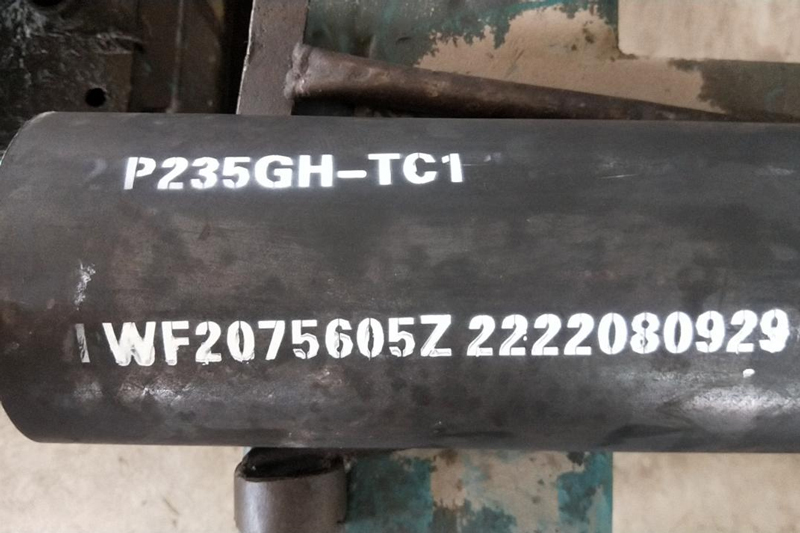

12. Marking & Packaging

- Pipes are marked with specifications (size, grade, standard) and bundled for shipment.

Key Differences Between ERW & HFW Pipes

| Feature | ERW (Traditional) | HFW (Modern) |

| Frequency | Low/Medium (10-400 kHz) | High (200-450 kHz) |

| Weld Quality | Good | Superior (less heat-affected zone) |

| Applications | Low/medium pressure pipes | High-strength, critical applications |

Applications of ERW/HFW Pipes

- Oil & gas pipelines

- Structural tubing

- Water supply systems

- Automotive & mechanical parts

This process ensures high efficiency, cost-effectiveness, and consistent quality for welded steel pipes.