Big diameter heavy wall thickness welded steel pipe LSAW

The production of Longitudinal Submerged Arc Welded (LSAW) steel pipes involves forming steel plates into a cylindrical shape and welding the longitudinal seam using the submerged arc welding (SAW) process. Below is a detailed step-by-step production process along with the main equipment used:

- 1. Raw Material Preparation-Steel Plate Inspection:- The process starts with checking the steel plates (usually API 5L, ASTM A36, or equivalent grades) for dimensions, chemical composition, and surface defects.-Edge Milling (Optional):- Plates may undergo edge milling to ensure smooth, straight edges for better welding quality.Equipment:- Ultrasonic testing (UT) machines- Plate edge milling machines

---

2. Plate Bending (JCO or UOE Forming)

The plate is bent into a cylindrical shape using one of the following methods:

a) JCO Forming (Step-by-Step Bending)

-Joggle (pre-bending the edges)

-Closing (gradual bending into a C-shape)

-Opening (final pressing into an O-shape)

b) UOE Forming (More Automated)

-U-pressing (first bend into a U-shape)

-O-pressing (final pressing into an O-shape)

-Expanding (optional, for precise roundness)

Equipment:

- Hydraulic press (JCO/UOE press)

- Plate pre-bending machine

- Edge crimping machine

---

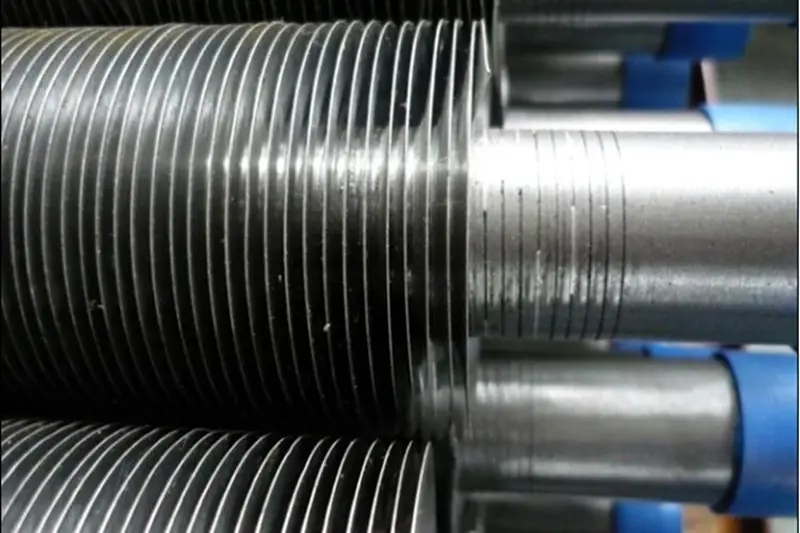

3. Welding (Longitudinal SAW)

-Internal Welding:

- Submerged Arc Welding (SAW) is performed on the inside of the pipe.

- A flux layer covers the arc to prevent oxidation.

-External Welding:

- The pipe is rotated, and SAW is applied on the outside seam.

- Multi-pass welding ensures high strength.

Equipment:

- Submerged Arc Welding (SAW) machines (internal & external)

- Welding wire and flux feeding system

---

4. Seam Inspection & Testing

-Non-Destructive Testing (NDT):

-Ultrasonic Testing (UT) – Detects internal defects.

-Radiographic Testing (RT) – X-ray inspection for weld integrity.

-Magnetic Particle Inspection (MPI) – Checks surface cracks.

Equipment:

- Ultrasonic flaw detectors

- X-ray or gamma-ray inspection systems

---

5. Pipe Expansion (Optional)

-Cold Expansion:

- The pipe is expanded hydraulically to improve roundness and dimensional accuracy.

Equipment:

- Pipe expander machine

---

6. Cutting & Beveling

- The pipe is cut to the required length using a saw or plasma cutter.

- Beveling is done at the ends for field welding compatibility.

Equipment:

- Pipe cutting saws

- Beveling machines

---

7. Hydrostatic Testing

- The pipe is filled with water and pressurized to check for leaks or weak points.

Equipment:

- Hydrostatic test pumps & pressure monitoring systems

---

8. Final Inspection & Coating

-Dimensional Check: Diameter, wall thickness, straightness.

-Surface Coating (Optional): Anti-corrosion coatings (e.g., 3LPE, FBE) may be applied.

Equipment:

- Coating application systems (spray or dipping)

- Ultrasonic thickness gauges

---

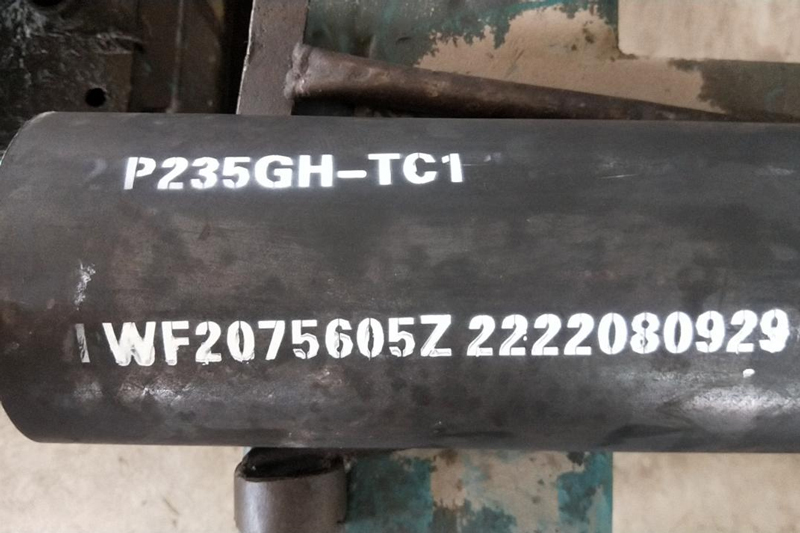

9. Marking & Storage

- Pipes are marked with specifications (grade, size, heat number, etc.).

- Stored in a warehouse before shipment.

Equipment:

- Paint marking machines

- Pipe handling cranes

Main Production Equipment Summary

|

Process Stage |

Key Equipment |

|

Plate Preparation |

Edge milling machine, UT testing machine |

|

Forming |

JCO/UOE press, hydraulic bender |

|

Welding |

Submerged Arc Welding (SAW) machines |

|

Inspection |

Ultrasonic testing (UT), X-ray (RT) machines |

|

Expansion |

Pipe expander |

|

Cutting & Beveling |

Plasma cutter, beveling machine |

|

Hydro Test |

Hydrostatic test unit |

|

Coating |

3LPE/FBE coating line |

|

Marking |

Laser/paint marking machine |

---

Final Notes

- LSAW pipes are widely used in oil & gas pipelines,structural applications, and water transmission due to their high strength and reliability.

- The JCO method is cost-effective for medium-volume production, while UOE is more automated for high-volume output.

Simple Flow Chart as follows:

[Steel Plate] → [Inspection] → [Edge Prep] → [JCO/UOE Forming] → [SAW Welding] →

[Weld Inspection] → [Expansion] → [Cutting] → [Hydro Test] → [Coating] → [Marking] → [Finished Pipe]