- Carbon & Carbon Alloy Steel

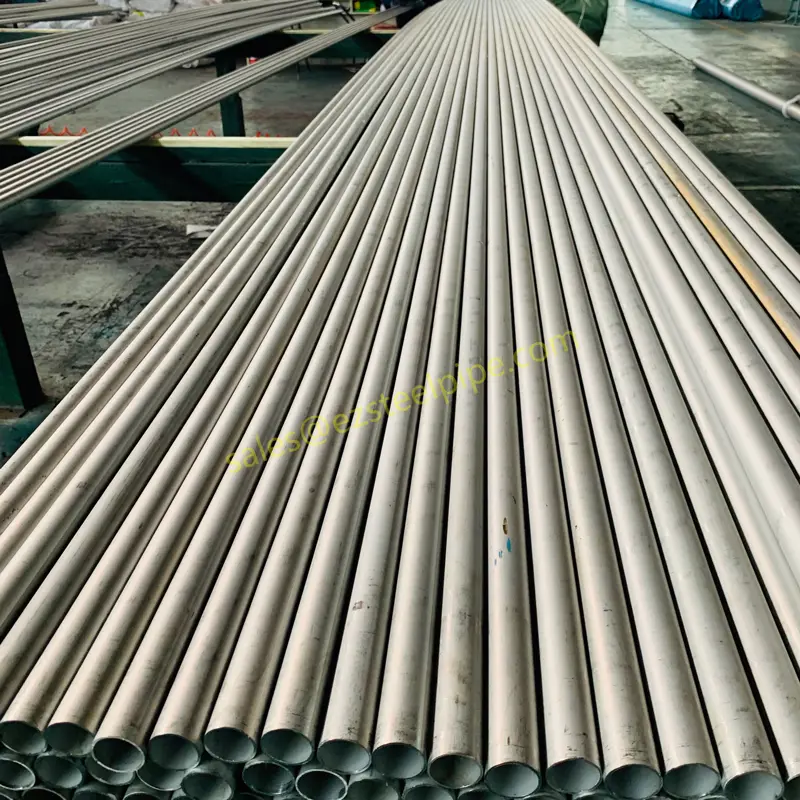

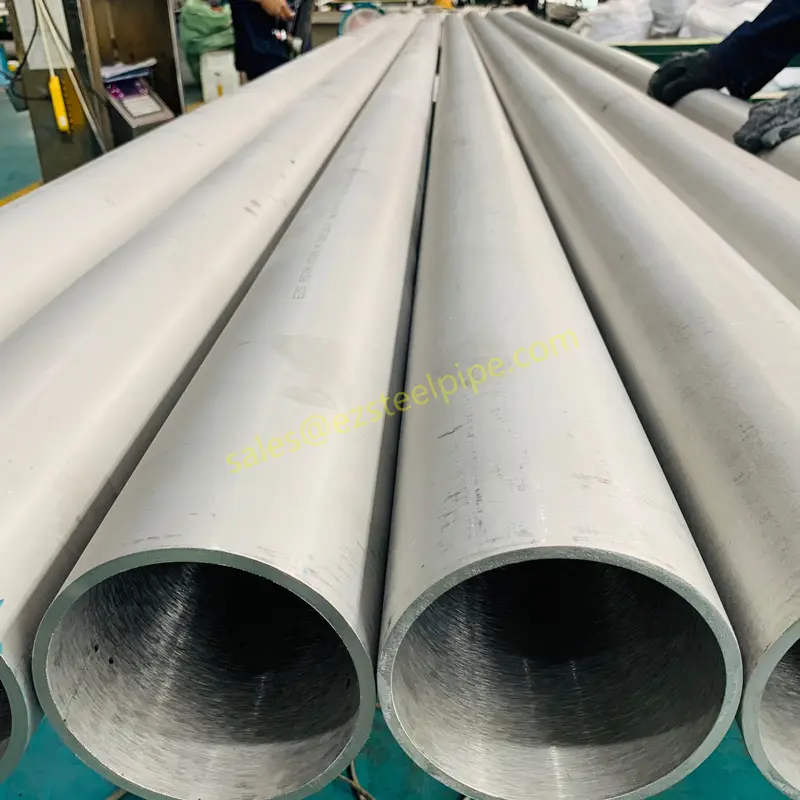

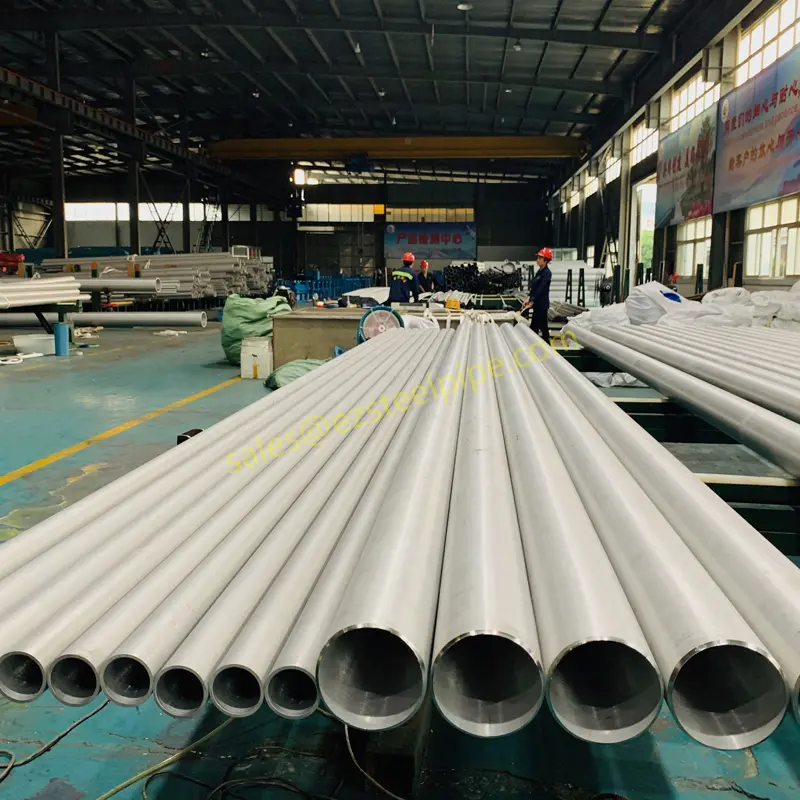

- Stainless Steel

- Copper & Nickel Alloy

- Heat Efficiency Tubes

- Pipe Fittings

- Pipe Flanges

- Gasket, Stud Bolt &Nut

- Industrial Valves

01

GOST 9941 Seamless Stainless Steel Pipes for Corrosion-Resistant and Heat-Resistant Applications

Ordering Information

When ordering pipes under GOST 9941, the following must be specified:

- Pipe dimensions (outer diameter, wall thickness, length)

- Steel grade (chemical composition)

- Mechanical properties (if special requirements apply)

- Heat treatment condition

- Type of testing and inspection (non-destructive testing, hydrostatic testing, etc.)

- Additional requirements (surface finish, end preparation, marking, packaging)

Steel Grades and Chemical Composition

The standard covers austenitic, ferritic, and martensitic stainless steels, including but not limited to:

- Austenitic: 12Х18Н10Т (AISI 321), 08Х18Н10 (AISI 304), 10Х17Н13М2Т (AISI 316Ti)

- Ferritic: 08Х13 (AISI 409), 12Х17 (AISI 430)

- Martensitic: 20Х13 (AISI 420), 30Х13 (AISI 420 mod.)

Exact chemical composition limits are specified in the standard for each grade.

Manufacturing and Heat Treatment

- Pipes are produced by hot rolling, cold rolling, or cold drawing.

- Mandatory heat treatment (annealing, quenching, tempering) depending on the steel grade.

Mechanical Properties

- Tensile strength, yield strength, elongation requirements are specified per steel grade.

- Hardness limits may apply for certain grades.

Inspection & Testing Requirements

- Hydrostatic testing (unless exempted for certain applications).

- Non-destructive testing (NDT) (ultrasonic or eddy current testing as required).

- Visual inspection for surface defects.

- Dimensional checks (outer diameter, wall thickness, straightness).

- Chemical analysis (verification of composition).

- Mechanical tests (tensile, hardness, flattening, flaring, or bending tests if specified).

Surface Quality & Defect Limitations

- Pipes must be free from cracks, laps, and other harmful defects.

- Minor surface imperfections may be allowed if within permissible limits.

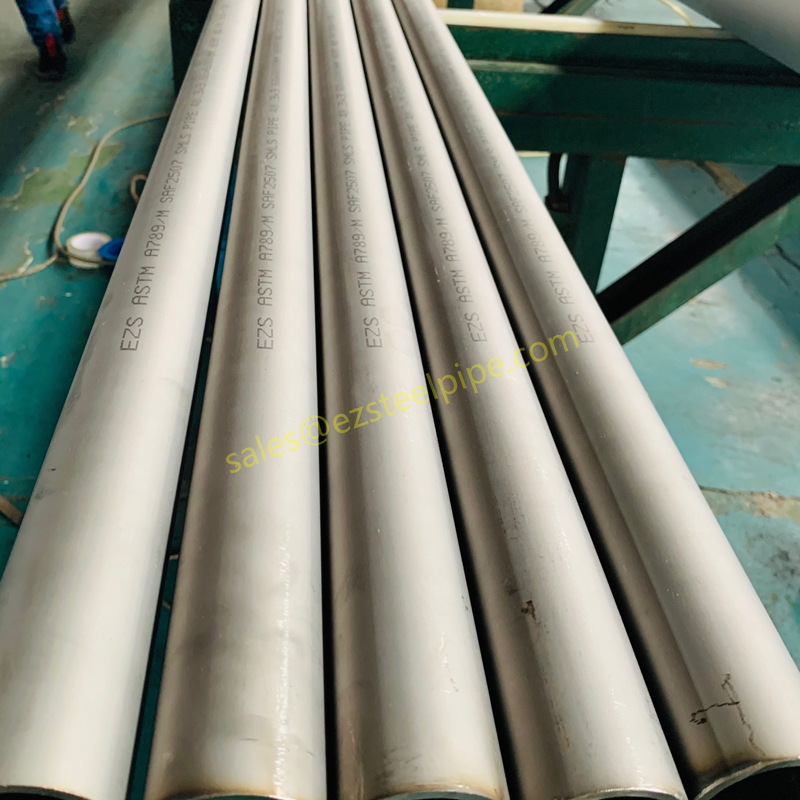

Marking and Packaging

- Each pipe must be marked with:

- Manufacturer’s name/trademark

- Steel grade

- Heat number

- Pipe dimensions

- Standard designation (GOST 9941)

- Packaging must ensure protection against damage during transport.

Certification & Compliance

- Manufacturer must provide a certificate of compliance with test results.

- Optional third-party inspection if specified in the order.

Want to order the same ? Contact us Now to send your request!