- Carbon & Carbon Alloy Steel

- Stainless Steel

- Copper & Nickel Alloy

- Heat Efficiency Tubes

- Pipe Fittings

- Pipe Flanges

- Gasket, Stud Bolt &Nut

- Industrial Valves

01

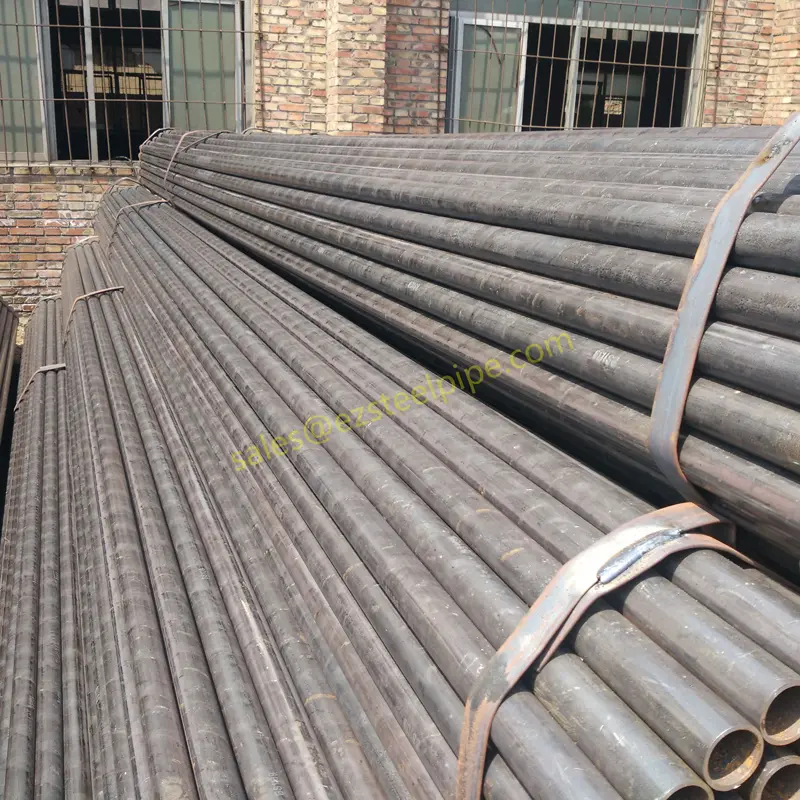

GB/T 8162-2018 General Seamless Steel Tubes for Structural and Mechanical Purposes

Ordering Information

Buyers should specify in contracts:

- Standard number (GB/T 8162-2018)

- Steel grade (e.g., 20#, 45#, Q345, etc.)

- Dimensions (outer diameter, wall thickness, length)

- Special requirements (e.g., heat treatment, testing)

Main Steel Grades

Common grades include:

- Carbon steels: 10#, 20#, 35#, 45#

- Alloy steels: 16Mn (Q345), 27SiMn, 40Cr, etc.

Manufacturing Process

- Hot-rolled or cold-drawn seamless tubes.

- Heat treatment (annealing, normalizing, or tempering) may be required based on grade.

Technical Requirements

- Chemical composition: Must comply with GB/T 699 (carbon steels) or GB/T 3077 (alloy steels).

- Mechanical properties: Tensile strength, yield strength, elongation per steel grade.

- Surface quality: Free from cracks, folds, and severe imperfections.

- Dimensional tolerances: Specified for outer diameter, wall thickness, and length.

Inspection & Testing

- Non-destructive testing: Optional unless specified (e.g., ultrasonic or eddy current testing).

- Mechanical tests: Tensile, hardness, or impact tests as required.

- Hydrostatic test: Not mandatory unless agreed upon.

Marking & Packaging

- Tubes are marked with manufacturer’s name, grade, size, and standard number.

- Packaging methods (bundling, protection against corrosion) per agreement.

Key Differences from Previous Versions

- GB/T 8162-2018 updated steel grades and tightened tolerances compared to the 2008 edition.

Main Steel Grades

1. Carbon Structural Steels (Based on GB/T 699-2015)

- 10#

- 20# (Most commonly used)

- 35#

- 45# (High-strength applications)

2. Alloy Structural Steels (Based on GB/T 3077-2015)

- Q345 (Equivalent to 16Mn, a low-alloy high-strength steel)

- 27SiMn (High strength, used in hydraulic supports)

- 40Cr (Chromium alloy, good hardness and wear resistance)

- 20Cr

- 35CrMo (Molybdenum alloy, high-temperature strength)

- 42CrMo (Higher strength than 35CrMo)

3. Other Grades (Less common but included in some applications)

- 15CrMo (Chromium-molybdenum alloy, heat-resistant)

- 12CrMoV (For high-temperature service)

Key Notes:

- 20# and Q345 are the most widely used grades for general structural purposes.

- Higher carbon grades (45#, 40Cr, 42CrMo) are used for high-strength mechanical components.

- Alloy steels (27SiMn, 35CrMo) are selected for specialized applications requiring toughness or heat resistance.

Want to order the same ? Contact us Now to send your request!