- Carbon & Carbon Alloy Steel

- Stainless Steel

- Copper & Nickel Alloy

- Heat Efficiency Tubes

- Pipe Fittings

- Pipe Flanges

- Gasket, Stud Bolt &Nut

- Industrial Valves

01

EN 10208 – Steel Pipes for Pipelines for Combustible Fluids

Ordering Information

When ordering pipes conforming to EN 10208, the following must be specified:

- Standard designation (EN 10208-1 or EN 10208-2)

- Type of pipe (seamless or welded)

- Dimensions (outside diameter, wall thickness, length)

- Steel grade (e.g., L245, L415, etc.)

- Requirement Class (A or B)

- Delivery condition (e.g., normalized, quenched and tempered)

- Inspection and testing requirements (e.g., non-destructive testing, hydrostatic test)

- Additional requirements (e.g., impact testing at lower temperatures, supplementary chemical analysis).

Main Steel Grades

Steel grades are designated by "L" followed by the minimum yield strength (in MPa). Common grades include:

| Grade | Yield Strength (MPa) | Tensile Strength (MPa) | Application |

| L245 | ≥245 | 415–760 | Low-pressure systems |

| L290 | ≥290 | 415–760 | General pipelines |

| L360 | ≥360 | 460–760 | Medium-pressure systems |

| L415 | ≥415 | 520–760 | High-strength pipelines |

| L450 | ≥450 | 535–760 | Demanding environments |

| L485 | ≥485 | 570–760 | High-pressure/critical use |

Note: Higher grades (e.g., L555, L690) may also be included depending on the version/supplement.

Inspection & Testing Requirements

For Requirement Class A (Basic):

- Chemical analysis (C, Si, Mn, P, S, etc.)

- Tensile test (yield strength, tensile strength, elongation)

- Hydrostatic test (minimum test pressure specified)

- Visual inspection (surface defects).

For Requirement Class B (Stringent):

- All tests from Class A, plus:

- Impact testing (Charpy V-notch at specified temperatures)

- Non-destructive testing (NDT) (ultrasonic, radiographic, or magnetic particle inspection for welds/seams)

- Additional mechanical tests (flattening test, bend test, or hardness test if required).

Other Key Requirements

- Delivery condition: Pipes may be supplied in normalized, quenched and tempered, or as-rolled condition.

- Dimensions & tolerances: Compliant with EN ISO 1127 (seamless) or EN ISO 1129 (welded).

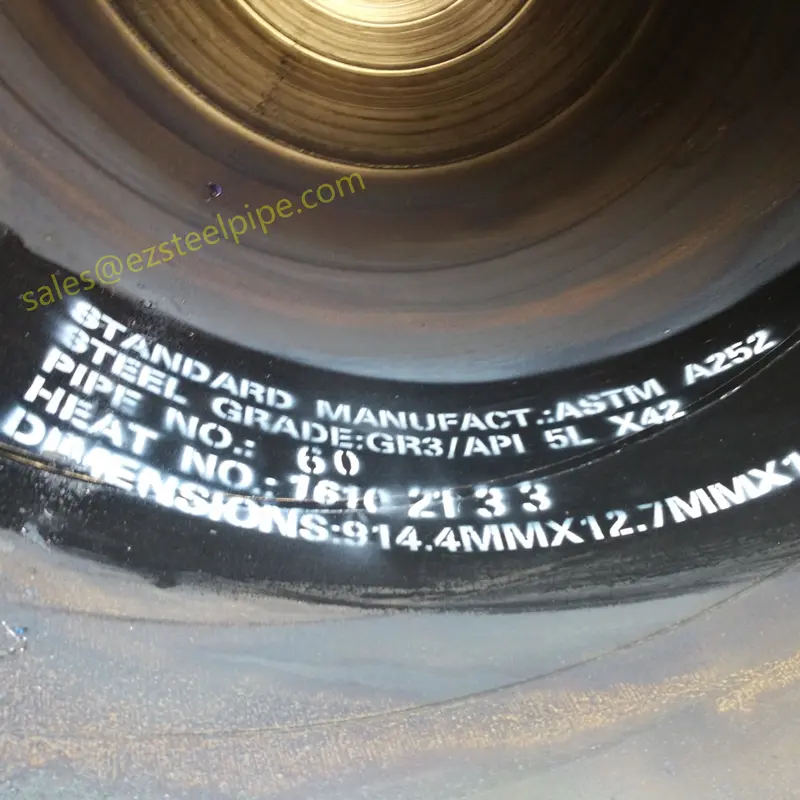

- Marking & certification: Pipes must be marked with standard, grade, manufacturer, and inspection certificate (EN 10204 Type 3.1 or 3.2).

Conclusion

EN 10208:2009 is a critical standard for steel pipes in combustible fluid transportation, with Class B pipes undergoing stricter testing for high-risk applications. Key considerations include material grade selection, inspection level, and certification requirements based on operational demands.

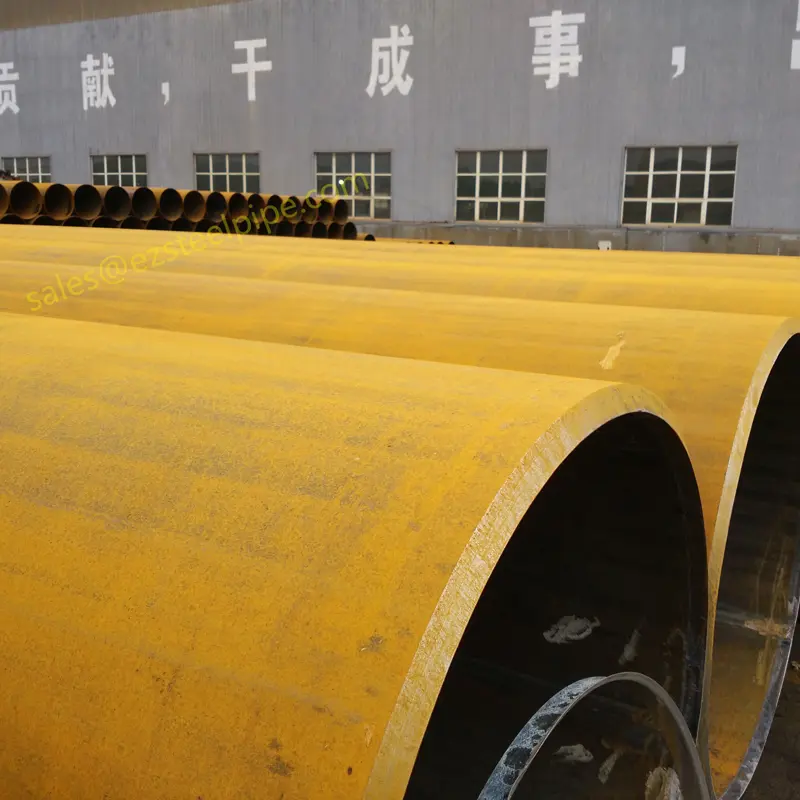

Want to order the same ? Contact us Now to send your request!