- Carbon & Carbon Alloy Steel

- Stainless Steel

- Copper & Nickel Alloy

- Heat Efficiency Tubes

- Pipe Fittings

- Pipe Flanges

- Gasket, Stud Bolt &Nut

- Industrial Valves

01

EEMUA Publication 234: Copper-Nickel Alloy Piping for Offshore Applications – Tubes

Ordering Information

When ordering Cu-Ni tubes per EEMUA 234, the following should be specified:

- Alloy designation (e.g., 90/10 Cu-Ni, 70/30 Cu-Ni)

- Dimensions (outer diameter, wall thickness, length)

- Temper (e.g., annealed, as-drawn)

- End finishes (plain, beveled, grooved)

- Certification requirements (e.g., EN 10204 3.1/3.2)

- Special testing (if required, e.g., corrosion testing)

Material Codes & Alloys

Common alloys covered:

- 90/10 Cu-Ni (UNS C70600) – General seawater service

- 70/30 Cu-Ni (UNS C71500) – Higher corrosion resistance

- Other variants (if applicable, with trace element controls)

Manufacturing & Chemical Composition

- Melting process: Typically electric furnace with controlled impurity levels.

- Chemical composition: Limits for Cu, Ni, Fe, Mn, and trace elements to ensure corrosion resistance.

Mechanical Properties

- Tensile strength, yield strength, elongation per alloy and temper.

- Hardness requirements (Rockwell or Vickers, as applicable).

Dimensional Tolerances

- Outside diameter, wall thickness, straightness, and length tolerances specified.

- Surface finish requirements (e.g., smooth, free from defects).

Inspection & Testing Requirements

- Non-destructive testing (NDT): Eddy current, ultrasonic, or hydrostatic testing.

- Corrosion testing (if specified, e.g., ASTM G48 for pitting resistance).

- Visual inspection for surface defects.

- Certification: Mill test reports (MTRs) to EN 10204 3.1 or 3.2.

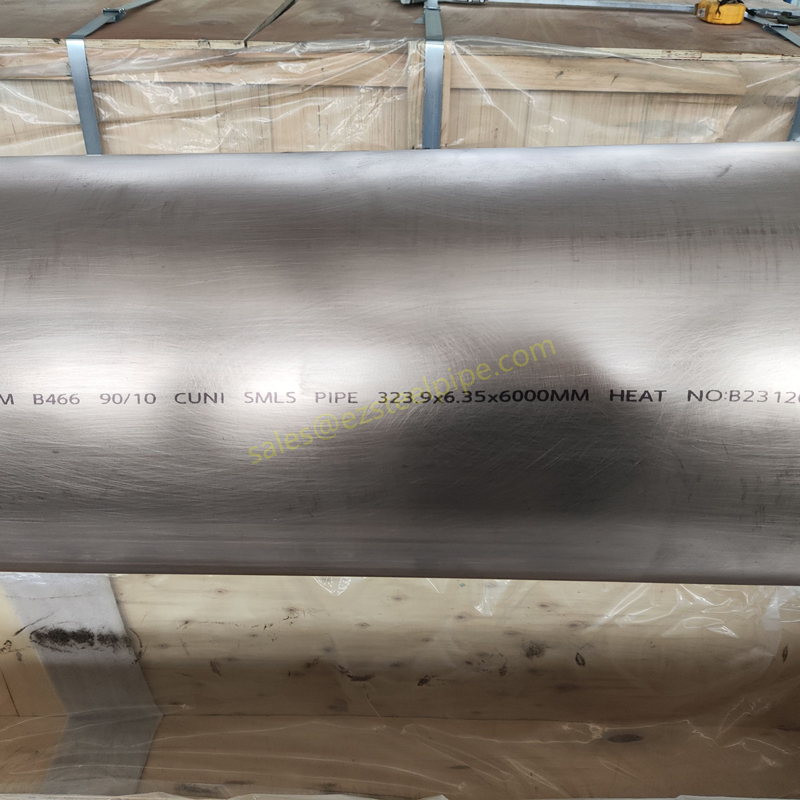

Marking & Packaging

- Permanent marking with alloy grade, heat number, size, and manufacturer.

- Protective packaging to prevent damage during transport.

Compliance & Certification

- Compliance with ASTM, EN, or other international standards as applicable.

- Third-party inspection (if required by purchaser).

Conclusion

EEMUA 234 provides a comprehensive specification for Cu-Ni alloy tubes in offshore environments, ensuring material integrity through strict chemical, mechanical, and inspection criteria. It is widely referenced in the oil & gas, marine, and desalination industries.

Material Codes in EEMUA 234 (Latest Version)

1. Common Copper-Nickel Alloys

The standard typically includes the following alloys, identified by Unified Numbering System (UNS) and European (EN) designations:

| Alloy Type | UNS Number | EN Designation | Common Name |

| 90/10 Cu-Ni | UNS C70600 | CW 352H (EN 12451) | 90% Cu, 10% Ni |

| 70/30 Cu-Ni | UNS C71500 | CW 354H (EN 12451) | 70% Cu, 30% Ni |

2. Additional Referenced Standards

EEMUA 234 may also refer to material specifications from:

- ASTM B466 / B467 (Seamless & Welded Cu-Ni Tubes)

- ISO 13388 (Copper & Copper Alloys – Inspection & Testing)

- EN 12451 (Copper & Cu Alloy Tubes for Heat Exchangers)

3. Material Condition (Temper)

- Annealed (O) – Soft condition for forming

- As-Drawn (H) – Hard temper for higher strength

4. Traceability & Certification

- Heat numbers must be provided for material traceability.

- Certification per EN 10204 3.1 or 3.2 (Inspection Certificates).

Key Notes

- The 90/10 Cu-Ni (C70600) is most common for general seawater service.

- The 70/30 Cu-Ni (C71500) offers superior corrosion resistance for harsh offshore conditions.

Want to order the same ? Contact us Now to send your request!