- Carbon & Carbon Alloy Steel

- Stainless Steel

- Copper & Nickel Alloy

- Heat Efficiency Tubes

- Pipe Fittings

- Pipe Flanges

- Gasket, Stud Bolt &Nut

- Industrial Valves

01

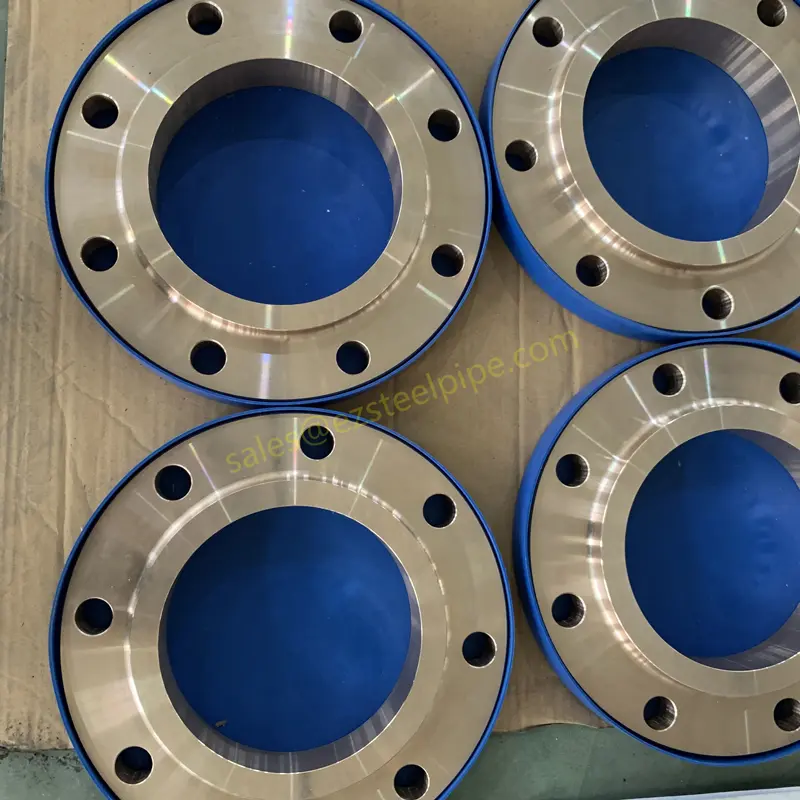

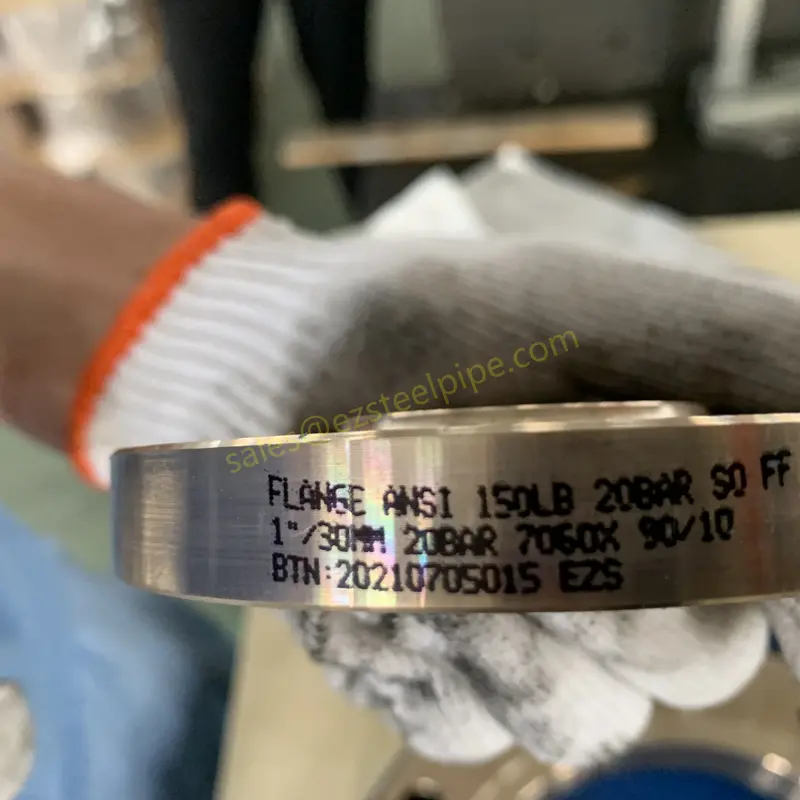

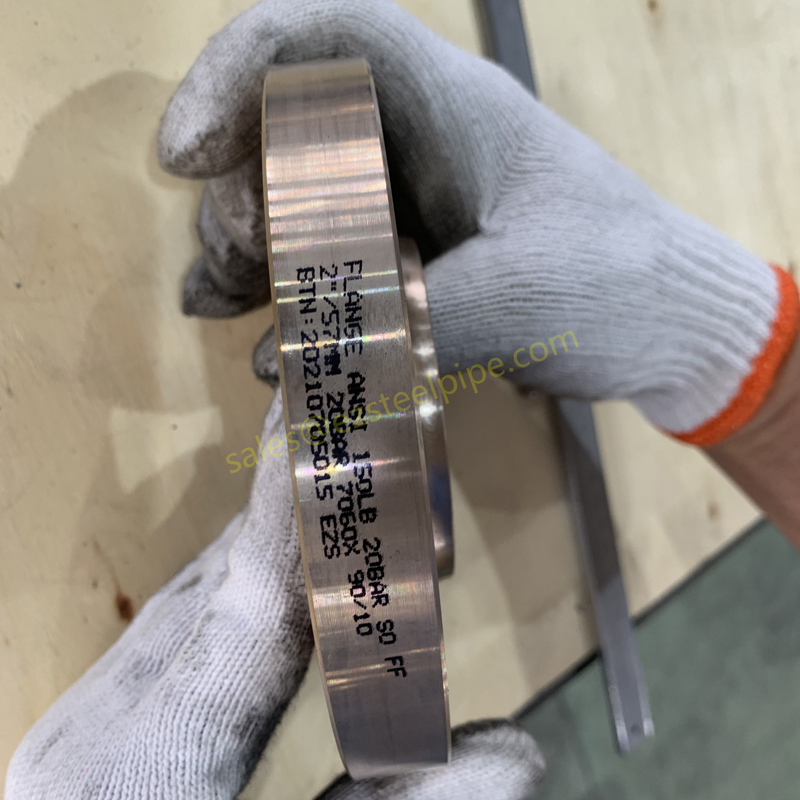

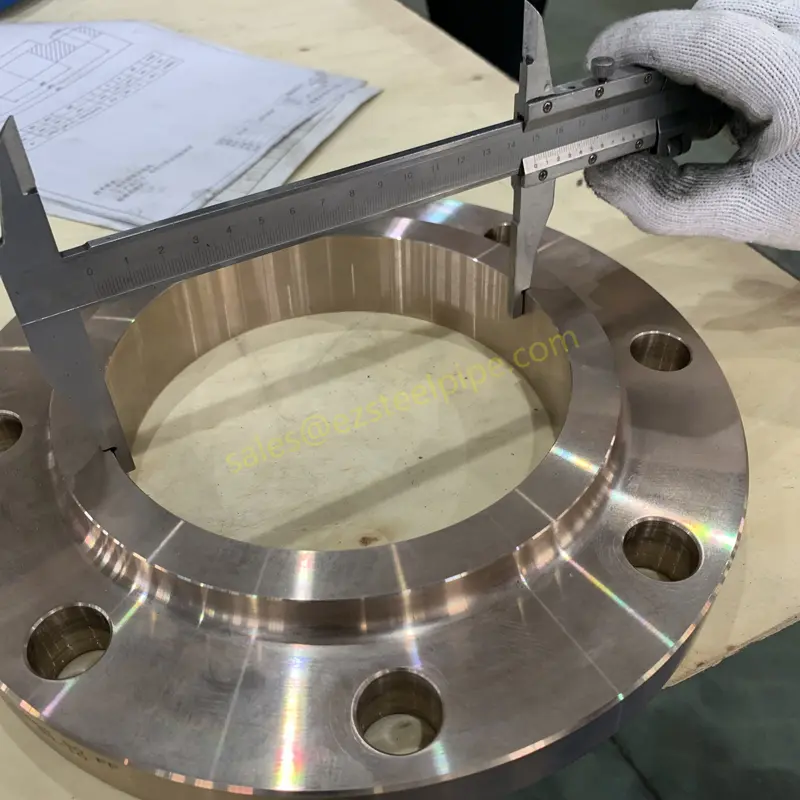

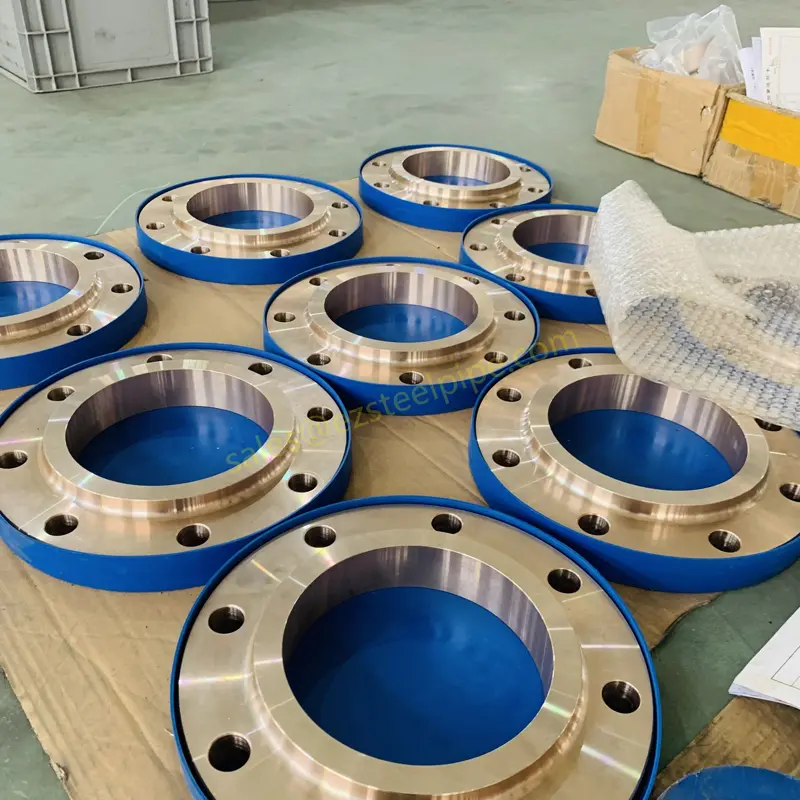

Copper Alloy Flange + Nickel Alloy Flange

Copper & Copper Alloy Flanges

Material Grades:

- Pure Copper (C10100, C10200, C11000) – High thermal/electrical conductivity.

- Brass (C27400, C37700) – Zinc-copper alloy, good machinability.

- Bronze (C90700, C95800) – Tin-copper alloy, excellent seawater resistance.

- Copper-Nickel (C70600, C71500) – 90/10 & 70/30 Cu-Ni, superior marine corrosion resistance.

Size Range:

- Diameter: ½" to 24" (larger sizes may require custom fabrication).

- Pressure Ratings: Class 150 to Class 600 (ASME B16.24), PN 6 to PN 40 (EN 1254).

Key Manufacturing Standards:

- ASME B16.24 – Cast/malleable copper alloy pipe flanges.

- EN 1254 – European copper alloy flanges (press-fit and threaded).

- ASTM B62 / B61 – Sand-cast and forged copper alloy standards.

- MIL-F-17191 – Military spec for naval copper-nickel flanges.

Special Applications:

- Marine & Shipbuilding (seawater cooling, ballast systems).

- HVAC & Refrigeration (ammonia, brine systems).

- Pharmaceutical & Food Processing (non-contaminating surfaces).

- Power Plant Condensers (high thermal conductivity).

Nickel & Nickel Alloy Flanges

Material Grades:

- Pure Nickel (UNS N02200, N02201) – Excellent corrosion resistance in alkaline environments.

- Monel (UNS N04400, N05500) – Nickel-copper alloy, resists seawater & acids.

- Inconel (UNS N06625, N07718) – Nickel-chromium, high-temperature strength.

- Hastelloy (UNS N10276, N06022) – Nickel-molybdenum-chromium, resists pitting & chlorides.

Size Range:

- Diameter: ½" to 48" (standard), larger sizes available for custom orders.

- Pressure Ratings: Class 150 to Class 2500 (ASME B16.5/B16.47).

Key Manufacturing Standards:

- ASME B16.5 / B16.47 – Standard for nickel alloy flanges.

- ASTM B564 / B160 / B366 – Forged/wrought nickel alloy specifications.

- NACE MR0175/ISO 15156 – For sour service (H₂S environments).

- API 6A – Wellhead flanges for oil & gas.

Special Applications:

- Oil & Gas (Sour Service) – Resistant to H₂S and CO₂ corrosion.

- Chemical Processing – Handles sulfuric, hydrochloric, and acetic acids.

- Aerospace & Nuclear – High-temperature stability (Inconel 718).

- Desalination Plants – Copper-nickel (C70600) for seawater resistance.

Comparison of Copper vs. Nickel Flanges

| Feature | Copper Alloy Flanges | Nickel Alloy Flanges |

| Corrosion Resistance | Excellent in freshwater, seawater (Cu-Ni) | Superior in acids, chlorides, H₂S |

| Temperature Range | -50°C to 200°C (limited for pure Cu) | -200°C to 1000°C (Inconel/Hastelloy) |

| Cost | Moderate (cheaper than nickel alloys) | Expensive (high nickel content) |

| Common Standards | ASME B16.24, EN 1254 | ASME B16.5, ASTM B564 |

| Primary Industries | Marine, HVAC, food processing | Oil & gas, chemical, aerospace |

Copper flanges are ideal for marine, HVAC, and low-pressure corrosive environments.

Nickel alloy flanges excel in extreme conditions (high temp, acids, sour gas).

Both are manufactured under ASME, ASTM, and EN standards, with nickel alloys often requiring NACE compliance for oilfield use.

Want to order the same ? Contact us Now to send your request!