- Carbon & Carbon Alloy Steel

- Stainless Steel

- Copper & Nickel Alloy

- Heat Efficiency Tubes

- Pipe Fittings

- Pipe Flanges

- Gasket, Stud Bolt &Nut

- Industrial Valves

01

Butt-Welding Pipe Fittings for Piping System

Butt-Welding Elbow

- Purpose: Changes the direction of flow in a piping system.

- Types:

- 90° Elbow: Changes direction by 90 degrees.

- 45° Elbow: Changes direction by 45 degrees.

- 180° Elbow (Return Bend): Reverses flow direction completely.

- Materials: Carbon steel, stainless steel, alloy steel, duplex steel, etc.

- Ends: Beveled ends for welding.

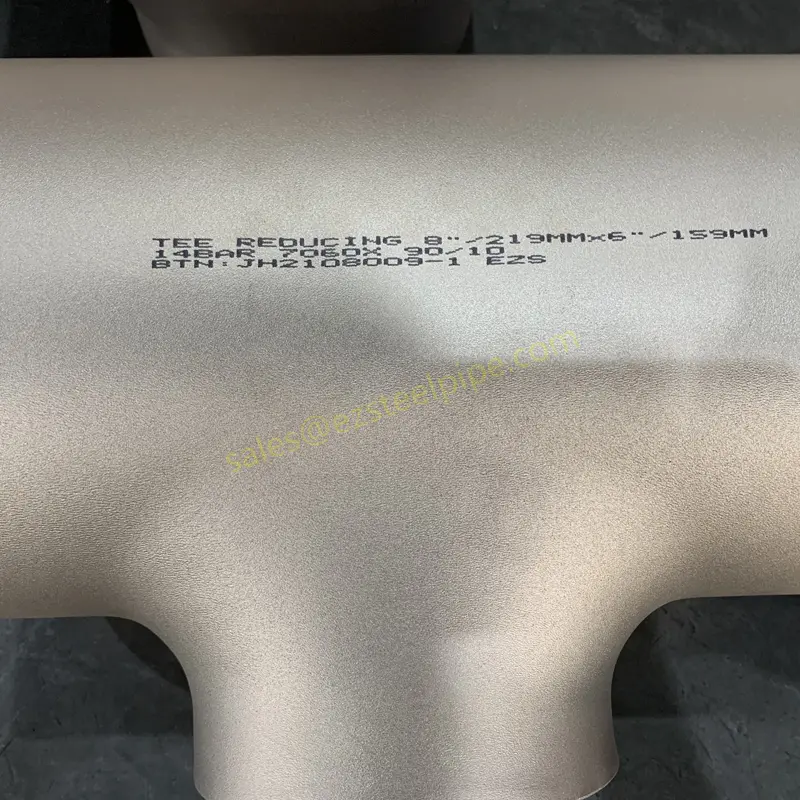

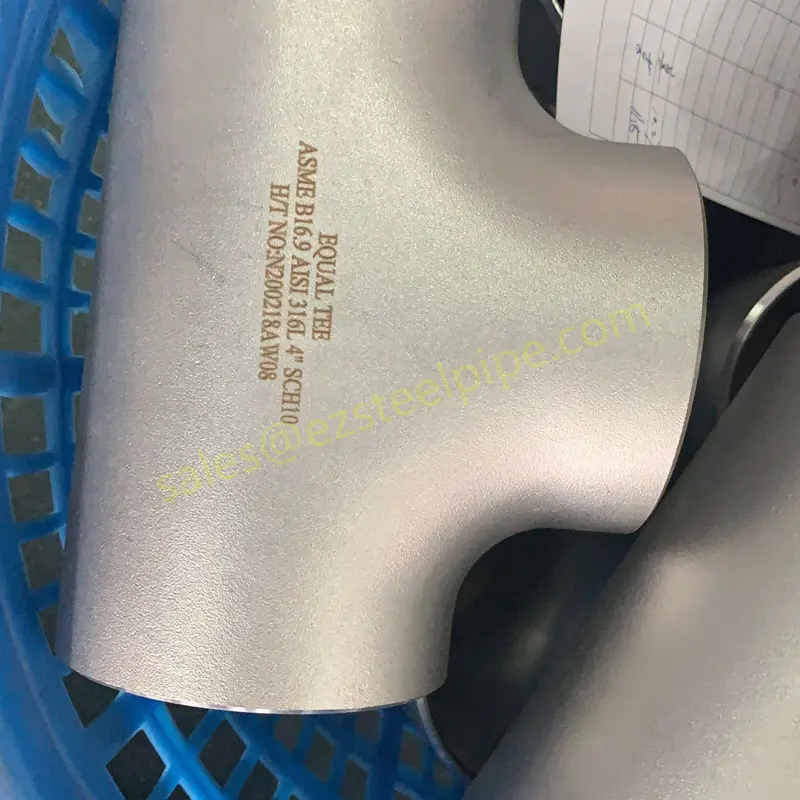

Butt-Welding Tee

- Purpose: Combines or splits fluid flow in a piping system.

- Types:

- Equal Tee: All three ends are the same size.

- Reducing Tee: One branch is smaller than the main run.

- Applications: Used in pipelines where flow diversion is needed.

Butt-Welding Reducer

- Purpose: Connects pipes of different diameters.

- Types:

- Concentric Reducer: Aligns the centerlines of both pipes (used in vertical lines).

- Eccentric Reducer: Offsets one side (used to avoid air pockets in horizontal lines).

- Applications: Pump inlets, pipe size transitions.

Butt-Welding Cap

- Purpose: Seals the end of a pipe, terminating flow.

- Features:

- Hemispherical or flat design.

- Used for pressure testing or future expansion.

Butt-Welding Stub End (Lap Joint Stub End)

- Purpose: Used with lap joint flanges for easy disassembly.

- Features:

- One end is beveled for welding to the pipe, the other has a flared face to match the lap joint flange.

- Common in systems requiring frequent maintenance.

Butt-Welding Cross

- Purpose: Allows flow in four directions (rarely used due to high stress).

- Applications: Specialized industrial piping systems.

Butt-Welding Union (Limited Use)

- Purpose: Connects pipes but is less common due to welding requirements.

- Alternative: Flanged connections are preferred for disassembly.

Advantages of Butt-Welding Fittings:

✔ High Strength & Leak-proof – No weak points like threads.

✔ Smooth Flow – No internal obstructions.

✔ Suitable for High-Pressure/Temperature – Ideal for oil & gas, chemical plants, power plants.

✔ Long Service Life – Less prone to corrosion at joints.

Standards & Specifications:

- ASME B16.9 (Factory-made wrought butt-welding fittings).

- ASME B16.28 (Wrought steel butt-welding short radius elbows).

- MSS SP-43 (Lightweight stainless steel fittings).

- ASTM/ANSI/API Standards (Material-specific requirements).

Common Materials:

- Carbon Steel (ASTM A234 WPB)

- Stainless Steel (ASTM A403 WP304/316)

- Alloy Steel (ASTM A234 WP5/WP9/WP11)

- Duplex & Super Duplex (ASTM A790/A928)

Applications:

- Oil & Gas Pipelines

- Chemical & Petrochemical Plants

- Power Generation (Steam & Water Lines)

- Shipbuilding & Offshore Platforms

- HVAC & Water Treatment Systems

Butt-welding fittings are preferred in critical applications due to their reliability and structural integrity. Proper welding techniques (e.g., TIG, MIG, or SMAW) and post-weld heat treatment (PWHT) ensure optimal performance.

Butt-welding (BW) pipe fittings must adhere to strict international standards to ensure quality, dimensional consistency, and material integrity. Below are the most widely recognized standards governing their production:

1. ASME (American Society of Mechanical Engineers) Standards

a) ASME B16.9

- Scope: Covers factory-made wrought carbon/alloy steel butt-welding fittings (elbows, tees, reducers, caps, etc.).

- Key Requirements:

- Dimensions, tolerances, and pressure ratings.

- Materials: Carbon steel (A234 WPB), stainless steel (A403), alloy steel (A234 WP5-WP91).

- Common Applications: Oil & gas, power plants, chemical industries.

b) ASME B16.25

- Scope: Standardizes welding end preparations (bevel design) for butt-welding fittings.

- Key Requirements:

- Bevel angles, root face, and groove dimensions for seamless welding.

c) ASME B16.28

- Scope: Covers short-radius elbows (wrought steel) for tight spaces.

- Pressure Ratings: Matches ASME B16.9 but with a smaller bend radius.

2. MSS (Manufacturers Standardization Society) Standards

a) MSS SP-43

- Scope: Lightweight stainless steel butt-welding fittings (similar to ASME B16.9 but with thinner walls).

- Applications: Low-pressure systems (e.g., food processing, water treatment).

b) MSS SP-75

- Scope: High-strength wrought carbon/alloy steel fittings for high-pressure applications.

- Materials: ASTM A860 (e.g., WPHY 42, 52, 60, 65, 70).

c) MSS SP-73

- Scope: Brazing and socket-welding fittings (less common for BW but referenced for hybrid systems).

3. ASTM (American Society for Testing and Materials) Material Standards

a) ASTM A234

- Scope: Carbon/alloy steel pipe fittings (e.g., WPB, WP5, WP9, WP11).

- Grades: Vary by temperature/pressure resistance.

b) ASTM A403

- Scope: Stainless steel fittings (e.g., WP304, WP316, WP321).

- Sub-types:

- WP (Wrought Product): Standard fittings.

- CR (Corrosion Resistant): For aggressive environments.

c) ASTM A420

- Scope: Low-temperature carbon steel fittings (e.g., WPL6 for -46°C/-50°F service).

4. EN (European Norm) Standards

a) EN 10253

- Scope: Butt-welding fittings for carbon/alloy steel (Part 1-4).

- Key Differences vs. ASME:

- EN 10253-1: Non-alloy steel fittings.

- EN 10253-2: Alloy steel with inspection/testing requirements.

- EN 10253-3/4: Stainless steel fittings.

b) EN 1092

- Scope: Flanges (complementary to BW fittings).

5. ISO (International Organization for Standardization) Standards

a) ISO 3419

- Scope: Non-alloy and alloy steel butt-welding fittings (similar to ASME B16.9).

b) ISO 5251

- Scope: Stainless steel BW fittings (equivalent to ASTM A403).

6. JIS (Japanese Industrial Standards)

a) JIS B2311

- Scope: Carbon/alloy steel butt-welding fittings.

- Grades: Similar to ASTM/ASME but with local material codes (e.g., JIS G3454).

7. GOST (Russian Standards)

a) GOST 17375

- Scope: Steel BW elbows, tees, reducers (common in CIS countries).

- Pressure Classes: PN6 to PN100.

Key Considerations for Selection

1. Material Compatibility: Match ASTM/EN grades to fluid/service conditions.

2. Dimensional Compliance: ASME B16.9 vs. EN 10253 (slight size differences).

3. Pressure Ratings: Align with ASME B16.5 (flanges) or EN 1092.

4. Certifications:

- PED 2014/68/EU (Europe).

- NACE MR0175 (H2S service).

- NORSOK (L-150) for offshore.

Comparison Table: ASME vs. EN Standards

| Feature | ASME B16.9 | EN 10253 |

| Scope | Factory-made fittings | Carbon/stainless steel |

| Pressure | Class 150-2500 | PN2.5-PN100 |

| Materials | ASTM A234/A403 | P235GH, 316L, etc. |

| Testing | Hydrostatic optional | Mandatory for EN 10253-2/4 |

Want to order the same ? Contact us Now to send your request!