- Carbon & Carbon Alloy Steel

- Stainless Steel

- Copper & Nickel Alloy

- Heat Efficiency Tubes

- Pipe Fittings

- Pipe Flanges

- Gasket, Stud Bolt &Nut

- Industrial Valves

01

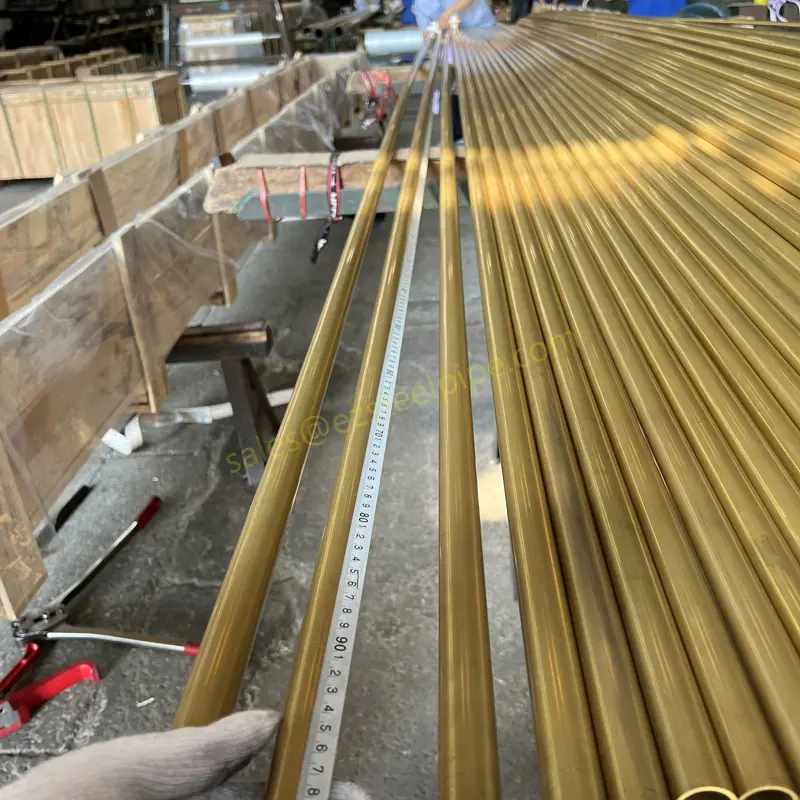

BS 2871 – Copper and Copper Alloy Tubes

Ordering Information

When ordering tubes conforming to BS 2871, the following details should be specified:

- Standard designation (e.g., BS 2871)

- Alloy code/number (e.g., C106, C122)

- Temper/condition (e.g., annealed, half-hard, hard)

- Dimensions (outer diameter, wall thickness, length)

- Type of tube (seamless or welded)

- Special requirements (e.g., pressure testing, surface finish)

Material Codes & Alloys

BS 2871 classifies copper and copper alloy tubes under different parts, including:

- Part 1: Copper tubes for water, gas, and sanitation (e.g., C106 – Phosphorus deoxidized copper)

- Part 2: Copper alloy tubes (e.g., brass, aluminum bronze)

- Part 3: Seamless copper tubes for heat exchangers

Common material codes:

- C101 – High-conductivity copper

- C106/C107 – Phosphorus deoxidized copper (suitable for welding)

- C122 – Phosphorus deoxidized copper with higher phosphorus content

Mechanical & Chemical Properties

- Tensile strength, elongation, and hardness vary based on temper (annealed, hard-drawn, etc.).

- Chemical composition limits for copper purity and alloying elements (e.g., phosphorus, zinc, lead).

Inspection & Testing Requirements

BS 2871 mandates several inspection and testing procedures, including:

- Dimensional checks (outer diameter, wall thickness, straightness)

- Visual inspection (surface defects, cracks, dents)

- Mechanical testing (tensile, hardness, flaring, flattening tests)

- Hydrostatic/pressure testing (for pressure applications)

- Non-destructive testing (NDT) (if specified)

Tolerances

- Diameter and wall thickness tolerances are specified based on tube type and size.

- Length tolerances for straight and coiled tubes.

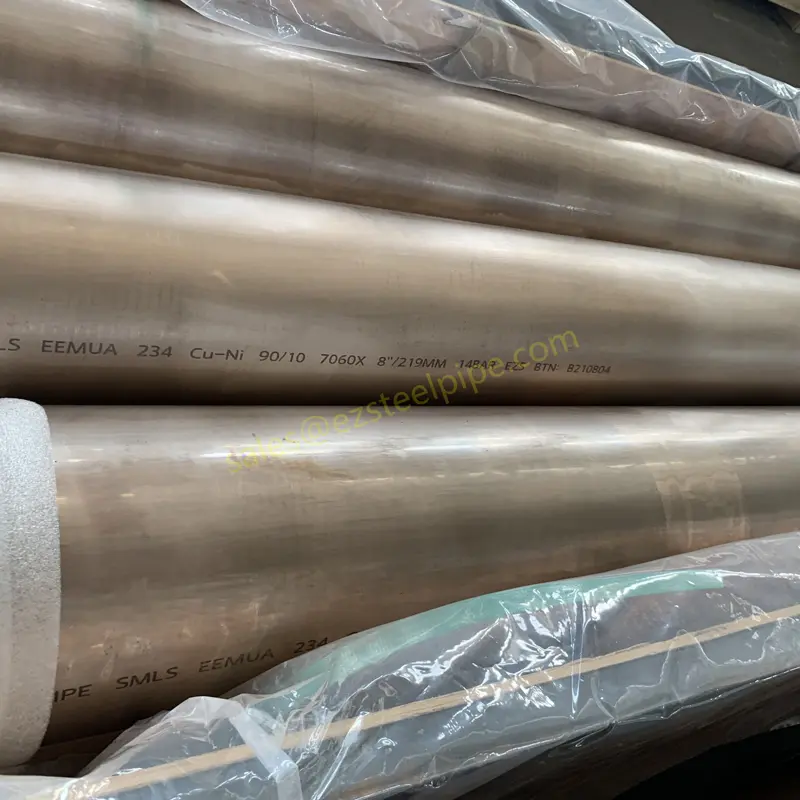

Marking & Certification

- Tubes must be marked with:

- Manufacturer’s name/trademark

- Alloy designation

- Temper condition

- Standard number (BS 2871)

- Certification (mill test certificates may be required for compliance).

Packaging & Storage

- Tubes should be protected from mechanical damage and corrosion.

- Packaging methods (bundling, boxing, or crating) depend on customer requirements.

The BS 2871 standard covers various copper and copper alloy tubes, divided into different parts. Below is a list of the material codes (alloy designations) specified in the latest editions of BS 2871 (as per historical revisions; verify with the current BSI standard for updates).

BS 2871 Material Codes (Copper & Copper Alloy Tubes)

Part 1: Copper Tubes for Water, Gas, and Sanitation

- C101 – High-conductivity copper (≥ 99.90% Cu)

- C103 – Oxygen-free copper (OFHC, ≥ 99.95% Cu)

- C106 – Phosphorus deoxidized copper (Cu-DHP, low residual phosphorus)

- C107 – Phosphorus deoxidized copper (Cu-DHP, higher phosphorus than C106)

- C108 – Silver-bearing copper (for high-strength applications)

- C110 – Electrolytic tough pitch copper (ETP, ≥ 99.90% Cu)

Part 2: Copper Alloy Tubes (Brass, Bronze, etc.)

- CZ101 – 70/30 Brass (70% Cu, 30% Zn)

- CZ102 – 60/40 Brass (60% Cu, 40% Zn)

- CZ103 – Admiralty brass (70% Cu, 29% Zn, 1% Sn, arsenic-bearing)

- CZ107 – Aluminum brass (76% Cu, 22% Zn, 2% Al, 0.04% As)

- CZ108 – Naval brass (62% Cu, 36.75% Zn, 1.25% Sn)

- CN102 – Aluminum bronze (e.g., CuAl10Fe5Ni5)

- CN107 – Nickel silver (Cu-Ni-Zn alloy)

Part 3: Seamless Copper Tubes for Heat Exchangers

- C101, C106, C107 (Same as Part 1, but with stricter tolerances for heat transfer applications)

Part 4: Copper Alloy Tubes for General Engineering

- CZ110 – Leaded brass (e.g., CuZn39Pb3)

- CZ112 – Free-cutting brass (high lead content)

- CS101 – Phosphor bronze (e.g., CuSn4, CuSn6)

Notes:

1. Temper Designations:

- O (Annealed) – Soft condition

- H (Hard-drawn) – Higher strength, less ductility

- HR (Half-hard) – Intermediate temper

2. Applications:

- C106/C107 – Plumbing, heating, refrigeration (common for brazing/welding).

- CZ101/CZ102 – General engineering, decorative applications.

- CZ107/CN102 – Corrosion-resistant uses (e.g., marine, condensers).

Want to order the same ? Contact us Now to send your request!