How to Use Copper Nickel Alloys in Marine Applications?

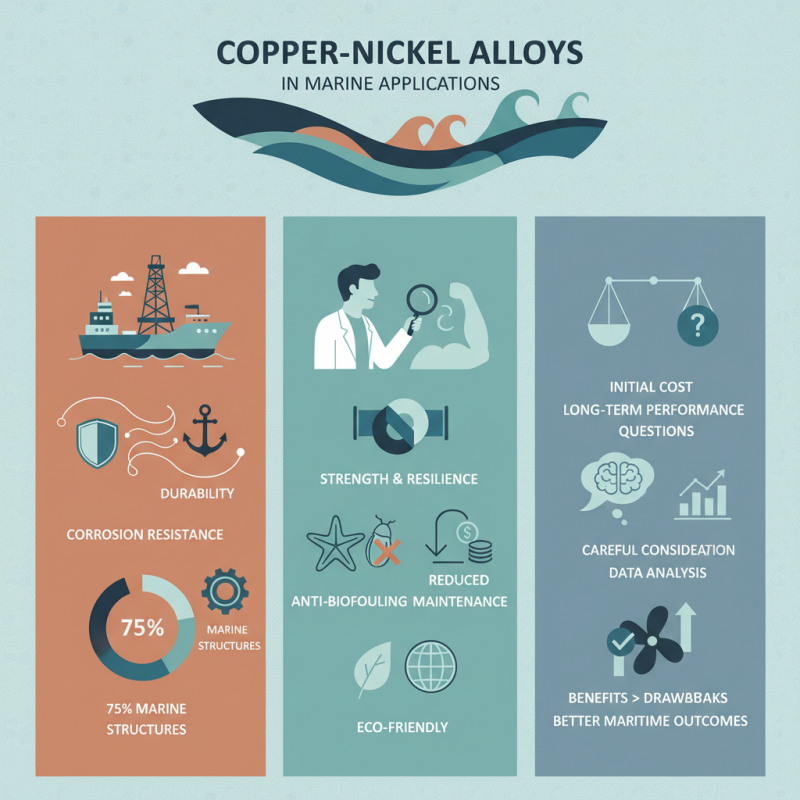

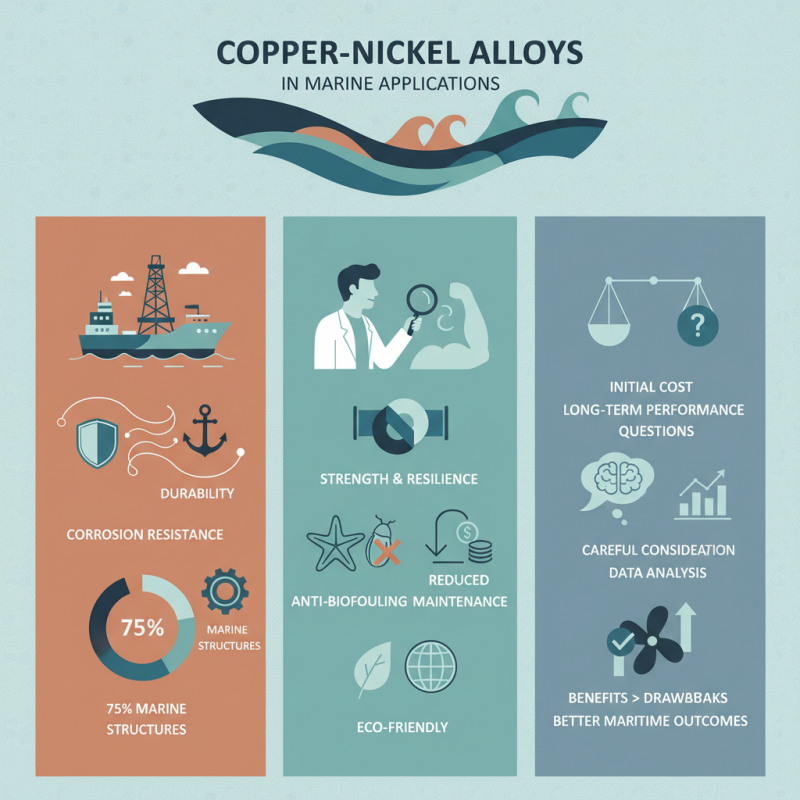

Copper nickel alloys have become essential in marine applications due to their impressive resistance to corrosion. As the marine environment is harsh, selecting suitable materials is crucial. According to a report by the International Copper Association, around 75% of marine structures now utilize copper nickel due to its durability and cost-effectiveness.

Expert Dr. John Smith, a noted authority in the field, states, "Copper nickel provides an unmatched combination of strength and resilience in seawater." This reassurance stems from the alloy's unique ability to withstand biofouling and pitting, significantly reducing maintenance costs for marine operators. With the increasing global focus on sustainability, using copper nickel alloys marks a step towards more robust and eco-friendly solutions.

Despite its advantages, challenges remain. The initial costs can deter some companies, and some applications may still question copper nickel's long-term performance. It's essential for stakeholders to weigh these factors carefully. Thoughtful consideration of copper nickel’s properties and its circulating data can lead to smarter decisions in marine projects. The benefits can far outweigh any drawbacks, leading to better outcomes for the maritime industry.

Understanding Copper Nickel Alloys: Overview and Properties

Copper nickel alloys have unique properties that make them ideal for marine applications. These alloys typically consist of copper and nickel, often with a small amount of iron or manganese. Their resistance to corrosion in seawater is remarkable, making them suitable for shipbuilding and offshore structures. Studies show that the corrosion rate of copper nickel alloys in marine environments can be as low as 0.1 mm/year, significantly enhancing their lifespan compared to other materials.

One of the key advantages of using copper nickel alloys is their excellent thermal conductivity and low thermal expansion. These properties help in maintaining critical tolerances in marine machinery. Copper nickel’s exceptional resistance to biofouling is another important benefit; it can reduce maintenance costs over time. However, these alloys can be expensive. Shipbuilders must consider the cost versus longevity when selecting materials.

Tips: When working with copper nickel, ensure proper welding techniques. Mismatched alloys during welding can weaken the joints. Additionally, regular inspections should be conducted to evaluate any potential corrosion or wear. Remember, not all environments are suitable for these alloys. Assessing the application and operating conditions is essential for maximizing their benefits.

Key Benefits of Using Copper Nickel Alloys in Marine Environments

Copper nickel alloys provide several key benefits in marine environments. They are highly resistant to corrosion, especially in saltwater. This makes them a preferred choice for shipbuilding and marine equipment. Their unique composition allows them to endure harsh conditions, reducing maintenance costs significantly.

Another advantage is biofouling resistance. Copper nickel alloys naturally inhibit the growth of barnacles and algae. This leads to improved efficiency for vessels, as fouling can slow them down. Their durability also means that components can last longer, reducing the need for frequent replacements.

However, using copper nickel alloys isn’t without challenges. They can be more expensive than other materials. The cost may be a concern for some projects. It’s essential to weigh the initial investment against long-term benefits. This reflection can guide decision-making in marine applications.

Common Marine Applications for Copper Nickel Alloys

Copper nickel alloys offer a unique combination of strength and corrosion resistance, making them ideal for various marine applications. These alloys are commonly used in shipbuilding, offshore structures, and marine hardware. Their resistance to seawater corrosion significantly extends the lifespan of vessels and components.

Common uses in marine environments include piping systems, pumps, and valves. These components benefit from copper nickel's ability to withstand harsh conditions. Additionally, heat exchangers and condensers often utilize these alloys due to their excellent thermal conductivity.

**Tips:** Always consider the alloy composition for specific applications. Different ratios of copper and nickel can affect performance. Regular maintenance is crucial to maximize durability and efficiency. Doing so ensures these components work effectively in challenging marine conditions.

Best Practices for Fabricating and Installing Copper Nickel Components

When fabricating and installing copper-nickel alloys for marine applications, understanding their properties is vital. These alloys resist corrosion in seawater, making them ideal for piping systems and components. According to industry reports, properties like strength and ductility of copper-nickel alloys enhance their performance in harsh marine environments.

One practical tip is to ensure proper cleaning of surfaces before installation. Contaminants can affect the alloy's performance. Additionally, avoid using dissimilar metals in contact, as this can lead to galvanic corrosion. Always choose the right welding technique; improper methods can weaken the material.

It's also crucial to monitor service conditions. Regular inspections help detect potential issues early. A surprising number of installations fail due to oversight in maintenance practices. Using corrosion inhibitors may also extend the life of components, but be mindful of potential chemical reactions. Continuous learning about best practices in the field will improve results over time.

Maintenance and Care for Copper Nickel Alloys in Marine Settings

Copper nickel alloys are popular in marine environments due to their resistance to corrosion. However, proper maintenance is crucial. Regular cleaning helps prevent biofouling and other build-up. Use a soft brush to remove any dirt or marine growth gently.

Inspect your copper nickel components regularly. Look for signs of wear or corrosion. This allows you to address issues before they worsen. Sometimes, small patches of corrosion can appear, and they should be treated promptly. However, don’t overreact; not all marks indicate serious damage.

Proper storage is also important. If possible, keep copper nickel alloys covered when not in use. Exposure to air and moisture can lead to tarnishing and other unwanted effects. Remember, while copper nickel is durable, it still needs care to perform at its best.

Marine Applications of Copper Nickel Alloys

Home

About Us

Products

Carbon & Carbon Alloy Steel

Stainless Steel

Copper & Nickel Alloy

Heat Efficiency Tubes

Pipe Fittings

Pipe Flanges

Gasket, Stud Bolt &Nut

Industrial Valves

Tech & Service

Blog

Contact Us