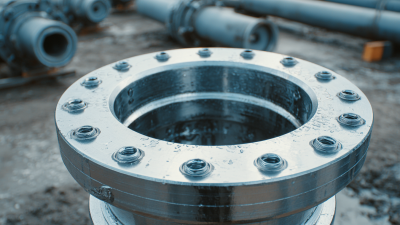

Pipe flanges are vital components in various industries. They connect pipes, valves, and other fittings securely. Understanding different types of flanges is essential for selecting the right one for a project. A common type is the slip-on flange, which easily slides over the pipe. It is straightforward to install. However, it may require welding on both sides, which can be time-consuming.

Another popular option is the weld neck flange. This type has a long tapered neck. It provides a smooth flow of liquids and gases. The design helps reduce stress at the base. However, it can be more expensive and complicated to install. Users often overlook this, but it can lead to errors in fitting.

Blind flanges are crucial when sealing off a system. They provide a clean and tight seal. While they are simple in design, users must ensure proper alignment and support. Misalignments can cause leaks, which is a common oversight. Overall, knowing these basic types is key in making informed decisions in flange selection.

Home

About Us

Products

Carbon & Carbon Alloy Steel

Stainless Steel

Copper & Nickel Alloy

Heat Efficiency Tubes

Pipe Fittings

Pipe Flanges

Gasket, Stud Bolt &Nut

Industrial Valves

Tech & Service

Blog

Contact Us