The Essential Guide to Choosing the Right Stainless Steel Flange for Your Project

When embarking on any engineering or manufacturing project, selecting the appropriate components is crucial, and this is especially true for Stainless Steel Flanges. The global flanges market is projected to reach approximately $30 billion by 2025, with a significant portion of this growth driven by the increasing demand for reliable and corrosion-resistant materials across various industries, including oil and gas, pharmaceuticals, and food processing.

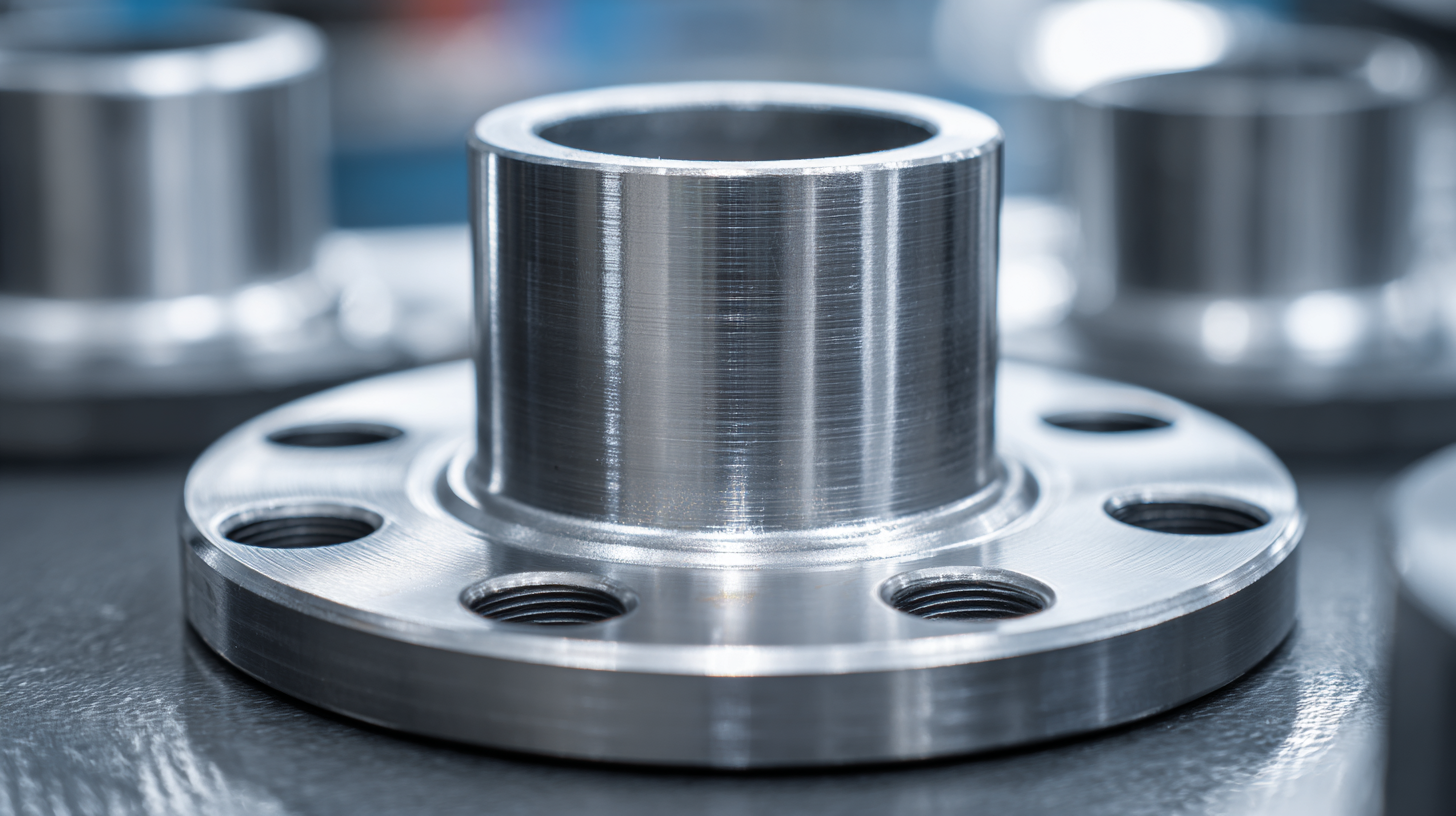

Stainless Steel Flanges are renowned for their strength and durability, making them essential in creating secure connections in piping systems. Understanding the different types of Stainless Steel Flanges, such as slip-on, blind, and weld neck flanges, as well as the relevant industry standards like ASTM and ANSI, is vital for ensuring the integrity and performance of any project. This guide aims to provide an in-depth overview to aid professionals in making informed decisions when selecting the right Stainless Steel Flange for their specific applications.

Top 5 Factors to Consider When Selecting Stainless Steel Flanges for Your Project

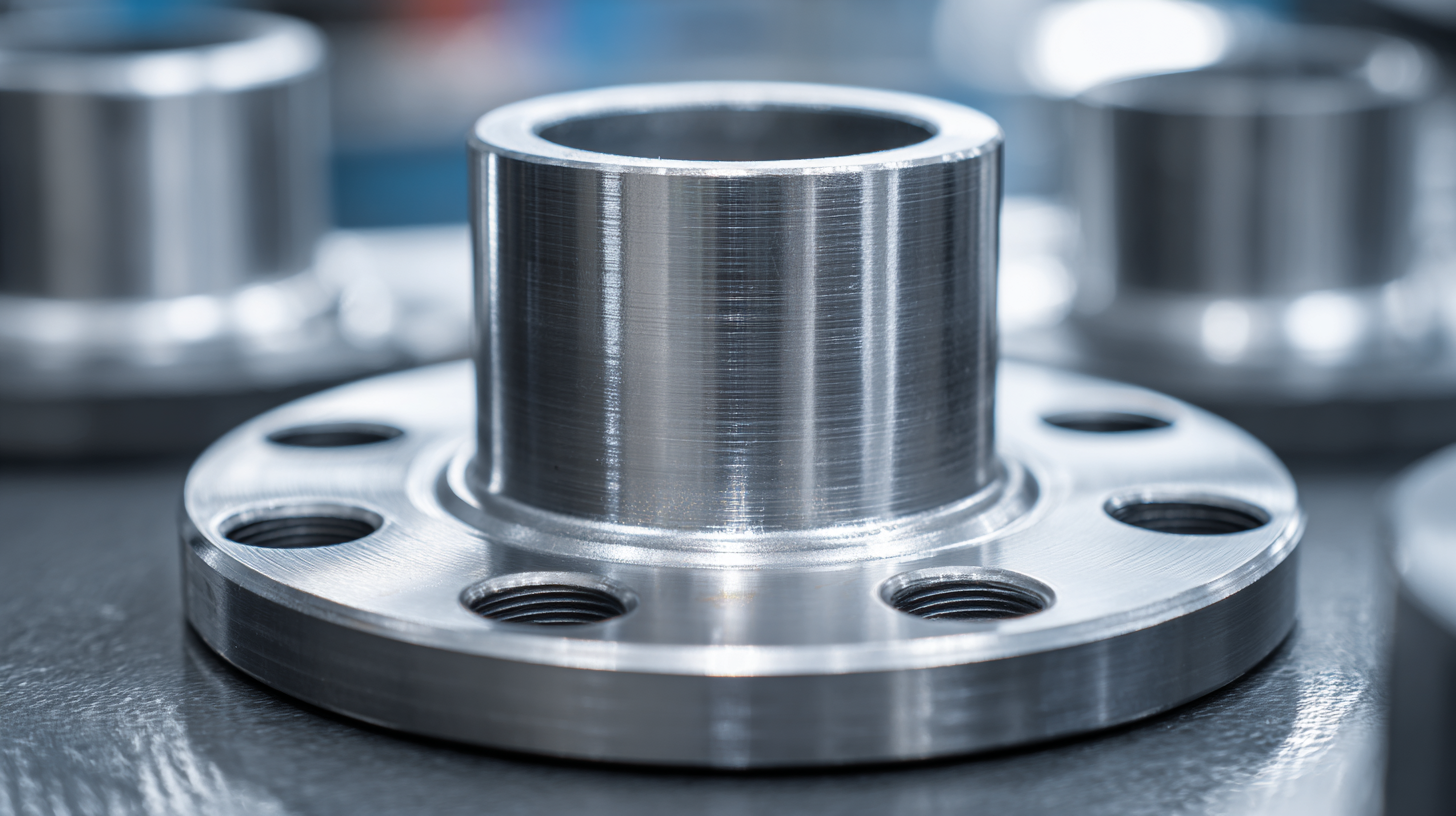

When selecting stainless steel flanges for your project, it's crucial to consider several key factors that can significantly influence both performance and longevity. First, the type of stainless steel used is paramount. Grades such as 304 and 316 offer varying levels of corrosion resistance and strength; for instance, a report from the Global Stainless Steel Market indicates that 316 stainless steel is particularly effective in highly corrosive environments, making it a preferred choice for marine applications (Market Research Future, 2022).

Another factor to consider is the flange size and pressure rating, as these directly affect the flange's ability to withstand operational conditions. According to the Pipe Flange Standards published by ASME, proper sizing guarantees a reliable seal, which is vital to avoid leaks and ensure safety during operations. Additionally, the manufacturing process plays a role in the flange's overall quality; flanges produced through forged processes generally exhibit superior mechanical properties compared to those made through casting, owing to better structural integrity (American National Standards Institute, 2021). These considerations collectively inform the decision-making process for ensuring optimal performance and safety in your piping systems.

7 Types of Stainless Steel Flanges and Their Best Applications

When selecting the appropriate stainless steel flange for your project, understanding the different types available and their best applications is paramount. There are seven primary types of stainless steel flanges: weld neck, slip-on, blind, socket weld, threaded, lap joint, and flange. Each type serves a unique purpose and is suited for specific operational requirements. For example, weld neck flanges are ideal for high-pressure applications due to their strong, tapered design that provides a smooth flow of liquids and gases, while slip-on flanges are easier to install and are often used in lower-pressure systems.

Industry reports indicate that demand for stainless steel flanges is steadily growing, with the global market expected to reach approximately $12 billion by 2026, driven primarily by advancements in the oil and gas sector and infrastructure development. For instance, blind flanges are critical in industries where safety and pressure containment are vital, allowing for easy access to pipelines for maintenance and modification. On the other hand, socket weld flanges are often used in high-pressure systems to ensure a robust connection, making them an essential choice in sectors like power generation. Understanding these distinctions will help you make informed decisions tailored to your project's specific needs.

The 4 Most Common Stainless Steel Grades Used in Flange Manufacturing

When selecting a stainless steel flange for your project, understanding the various grades available is crucial. The four most common stainless steel grades used in flange manufacturing are 304, 316, 321, and 410. Each of these grades has unique properties that make them suitable for different applications.

Grade 304 is often chosen for its excellent corrosion resistance and formability, making it ideal for a wide range of environments. On the other hand, Grade 316 offers enhanced resistance to chlorides, making it a preferred option in marine and chemical processing industries.

Grade 321 is known for its ability to withstand high temperatures, thanks to the addition of titanium, which helps prevent sensitization during welding. Finally, Grade 410, a martensitic stainless steel, is frequently used for its hardness and wear resistance, suitable for applications requiring strength and durability.

Choosing the right grade of stainless steel flange is essential to ensure optimal performance and longevity in your specific application. By understanding the differences among these grades, you can make an informed decision that will meet the demands of your project effectively.

Essential Do’s and Don’ts for Installing Stainless Steel Flanges

When it comes to installing stainless steel flanges, understanding the essential do's and don'ts can make a significant difference in the outcome of your project. Stainless steel flanges are known for their durability and resistance to corrosion, but improper installation can lead to leaks and system failures. According to industry reports, up to 30% of flange failures can be attributed to poor installation practices.

**Tips for Installation: Always ensure that the flange surfaces are clean and free from any debris before assembly. This ensures a proper seal and minimizes the potential for leaks. Do use appropriate gaskets and follow the manufacturer’s specifications on torque to achieve optimal tightness.**

Conversely, one common mistake involves overtightening the bolts, which can lead to distorting the flange and gasket material. As per the latest studies, nearly 20% of leaks in piping systems occur due to incorrect bolt alignment and tension.

**Tips for Avoiding Common Pitfalls: Avoid mismatched flange types and sizes, as this can compromise system integrity. Make sure to double-check compatibility before finalizing your installation.** By following these guidelines, you can enhance the reliability and longevity of your plumbing or piping systems.

6 Maintenance Tips to Ensure Longevity of Your Stainless Steel Flanges

Maintaining the longevity of stainless steel flanges is crucial for ensuring the durability and efficiency of your project. One essential tip is to regularly inspect the flanges for signs of wear or corrosion. Regular checks allow for the early detection of issues, which can prevent more significant damage and costly repairs. Additionally, it’s vital to keep the flanges clean and free from contaminants. Using a mild detergent and a soft cloth can help maintain their appearance and functionality.

Another important maintenance practice is ensuring that the bolts and nuts are correctly torqued. Over-tightening or under-tightening can lead to flange failure, so adhering to the manufacturer's specifications is critical. Furthermore, applying a protective coating or lubricant can help reduce the risk of corrosion and facilitate easier disassembly when needed. Lastly, if the flanges are exposed to harsh environments, consider using stainless steel alloys specifically designed for such conditions to enhance their lifespan. By following these maintenance tips, you can ensure your stainless steel flanges remain reliable for years to come.

Home

About Us

Products

Carbon & Carbon Alloy Steel

Stainless Steel

Copper & Nickel Alloy

Heat Efficiency Tubes

Pipe Fittings

Pipe Flanges

Gasket, Stud Bolt &Nut

Industrial Valves

Tech & Service

Blog

Contact Us