- Carbon & Carbon Alloy Steel

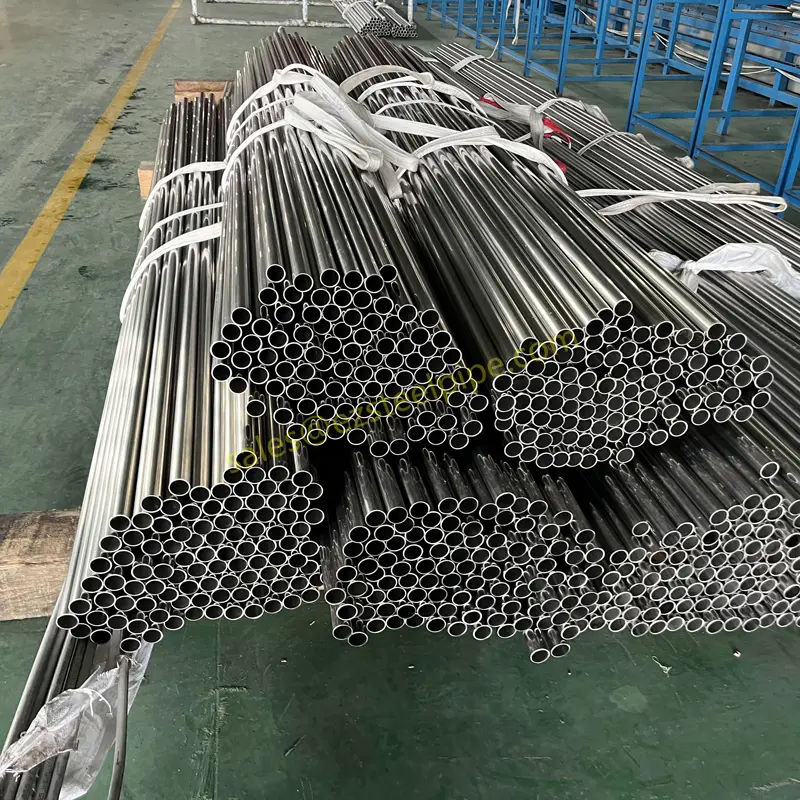

- Stainless Steel

- Copper & Nickel Alloy

- Heat Efficiency Tubes

- Pipe Fittings

- Pipe Flanges

- Gasket, Stud Bolt &Nut

- Industrial Valves

01

ASTM A213/A213M Seamless Ferritic and Austenitic Alloy-Steel Boiler, Superheater, and Heat-Exchanger Tubes

Ordering Information

Purchasers must specify:

- Quantity (length, number of pieces)

- Material grade (e.g., T11, T22, TP304H)

- Dimensions (OD, wall thickness)

- Condition (e.g., annealed, cold-worked)

- Test requirements (hydrostatic/nondestructive testing)

- Certification or inspection needs

- Any additional requirements (e.g., special tolerances)

Main Stainless Steel & Alloy Grades

Ferritic Grades

- T5, T9, T11, T12, T22 (e.g., T22: 2.25Cr-1Mo)

- T91, T92 (9Cr-1Mo-V-Nb)

Austenitic Grades

- TP304/304H, TP316/316H (18Cr-8Ni)

- TP321/321H (Ti-stabilized)

- TP347/347H (Nb-stabilized)

- S31025 (Super 304H), S31254 (6Mo super austenitic)

Manufacturing & Heat Treatment

- Tubes are seamless, made by hot-working or cold-working.

- Heat treatment (e.g., austenitic grades are solution-annealed; ferritic grades are normalized and tempered).

Chemical Composition

- Strict limits for C, Mn, P, S, Si, Cr, Ni, Mo, etc.

- H-grade variants (e.g., TP304H) have higher carbon for creep resistance.

Mechanical Properties

- Tensile strength, yield strength, elongation per grade (e.g., TP304H: ≥515 MPa tensile).

- Hardness limits (e.g., ≤90 HRB for austenitic grades).

Inspection & Testing Requirements

- Hydrostatic testing (mandatory, unless replaced by nondestructive testing).

- Nondestructive testing (NDT) (eddy current, ultrasonic, or pneumatic).

- Flattening, flare, or bend tests (if specified).

- Grain size verification for H-grades.

- Intergranular corrosion test (for austenitic grades, if required).

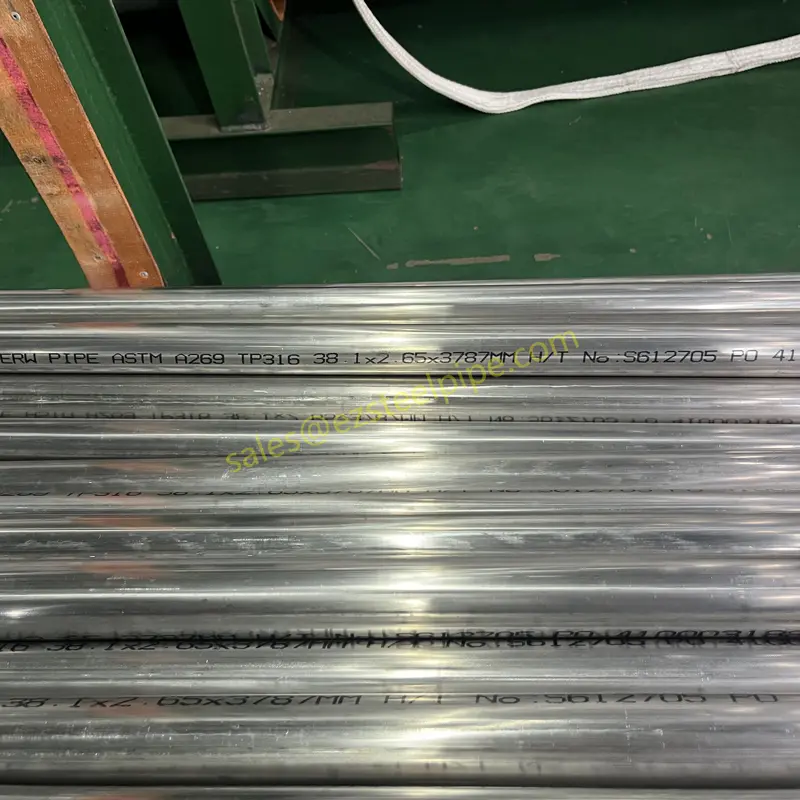

Certification & Marking

- Mill test reports (MTRs) must include chemical, mechanical, and test results.

- Marking: ASTM standard, grade, heat number, size, manufacturer’s name.

Tolerance Requirements

- OD, wall thickness, length, and straightness tolerances are specified.

Main Applications

Used in boilers, superheaters, heat exchangers, and other high-pressure/temperature environments.

Main Steel Grades

Here is a concise list of the main steel grades in ASTM A213/A213M, along with their key chemical components and mechanical properties (based on the latest version of the standard).

Ferritic and Martensitic Grades

(Low-Alloy Steels for High-Temperature Service)

| Grade | UNS No. | Chemical Composition (Key Elements, %) | Mechanical Properties |

| T5 | K51545 | 1.0Cr-0.5Mo (C≤0.15, Mn 0.30-0.60) | Tensile: ≥415 MPa Yield: ≥205 MPa Elong.: ≥30% |

| T9 | K90941 | 9Cr-1Mo (C 0.15-0.25, Si 0.25-1.0) | Tensile: ≥585 MPa Yield: ≥380 MPa Elong.: ≥20% |

| T11 | K11597 | 1.25Cr-0.5Mo-Si (C≤0.15) | Tensile: ≥415 MPa Yield: ≥205 MPa Elong.: ≥30% |

| T12 | K11562 | 1.25Cr-0.5Mo (C≤0.15) | Same as T11 |

| T22 | K21590 | 2.25Cr-1Mo (C≤0.15) | Tensile: ≥415 MPa Yield: ≥205 MPa Elong.: ≥30% |

| T91 | K90901 | 9Cr-1Mo-V-Nb (C 0.08-0.12) | Tensile: ≥585 MPa Yield: ≥415 MPa Elong.: ≥20% |

| T92 | K92460 | 9Cr-0.5Mo-2W-V-Nb (C 0.07-0.13) | Tensile: ≥620 MPa Yield: ≥440 MPa Elong.: ≥20% |

Austenitic Grades

(Stainless Steels for Corrosion & Heat Resistance)

| Grade | UNS No. | Chemical Composition (Key Elements, %) | Mechanical Properties |

| TP304 | S30400 | 18Cr-8Ni (C≤0.08, Mn≤2.0) | Tensile: ≥515 MPa Yield: ≥205 MPa Elong.: ≥35% |

| TP304H| S30409 | 18Cr-8Ni (C 0.04-0.10) | Same as TP304 but higher creep strength |

| TP316 | S31600 | 16Cr-12Ni-2Mo (C≤0.08) | Tensile: ≥515 MPa Yield: ≥205 MPa Elong.: ≥35% |

| TP316H| S31609 | 16Cr-12Ni-2Mo (C 0.04-0.10) | Same as TP316 but higher creep strength |

| TP321 | S32100 | 18Cr-10Ni-Ti (C≤0.08, Ti≥5xC) | Tensile: ≥515 MPa Yield: ≥205 MPa Elong.: ≥35% |

| TP321H| S32109 | 18Cr-10Ni-Ti (C 0.04-0.10) | Same as TP321 but higher creep strength |

| TP347 | S34700 | 18Cr-10Ni-Nb (C≤0.08, Nb≥10xC) | Tensile: ≥515 MPa Yield: ≥205 MPa Elong.: ≥35% |

| TP347H| S34709 | 18Cr-10Ni-Nb (C 0.04-0.10) | Same as TP347 but higher creep strength |

| S31025 (Super 304H) | S31025 | 18Cr-9Ni-3Cu-Nb (C 0.07-0.13) | Tensile: ≥590 MPa Yield: ≥240 MPa Elong.: ≥35% |

| S31254 (6Mo Super Austenitic) | S31254 | 20Cr-18Ni-6Mo-0.2N (C≤0.02) | Tensile: ≥650 MPa Yield: ≥300 MPa Elong.: ≥35% |

Key Notes

1. H-Grades (e.g., TP304H, TP316H) have higher carbon (0.04–0.10%) for improved creep resistance at high temperatures.

2. Stabilized Grades (TP321/TP347) contain Ti or Nb to prevent chromium carbide precipitation (sensitization).

3. Mechanical Properties are for annealed condition; cold-worked tubes may have higher strength but lower elongation.

4. Hardness Limits:

- Ferritic grades: Typically ≤250 HBW.

- Austenitic grades: ≤90 HRB (Rockwell B).

Want to order the same ? Contact us Now to send your request!